Motor calibration is a process that helps you guarantee your motor operates accurately and efficiently by measuring and adjusting sensors and settings. A calibration calculator simplifies this by analyzing sensor data and motor responses, automatically suggesting the best adjustments. Proper calibration prevents errors, extends motor lifespan, and improves performance. Keep your sensors clean, monitor regularly, and document your adjustments. Continuing will give you a clear understanding of how calibration tools work and how to use them effectively.

Key Takeaways

- A motor calibration calculator analyzes sensor data to find optimal settings for accurate motor performance.

- It detects deviations or errors in motor responses, helping to prevent malfunctions.

- The calculator automates adjustments of calibration parameters like voltage and timing for smooth operation.

- Proper calibration ensures sensors are accurate, reducing energy waste and extending motor lifespan.

- Regular use of the calculator maintains consistent motor performance and simplifies troubleshooting.

Understanding the Purpose of Motor Calibration

Understanding the purpose of motor calibration is essential because it guarantees your motor operates accurately and efficiently. Proper calibration helps ensure motor safety by preventing malfunctions that could lead to accidents or damage. When your motor is correctly calibrated, it performs at peak levels, reducing energy waste and extending its lifespan. Calibration also makes troubleshooting techniques more effective, allowing you to quickly identify issues related to misalignment, vibrations, or irregular performance. Without proper calibration, you might misinterpret symptoms or overlook underlying problems, risking further damage. Regularly calibrating your motor keeps it running smoothly, maintains safety standards, and simplifies maintenance. Ultimately, understanding its purpose helps you prevent costly errors and ensures your motor functions reliably over time.

Key Terms and Concepts in Motor Calibration

To calibrate your motor effectively, you need to understand key parameters that influence its performance. These calibration parameters determine how the motor responds to commands and adjustments. By grasping these concepts, you can optimize your motor’s response for better accuracy and efficiency. Understanding system security assessments can also help identify vulnerabilities that may affect motor control systems.

Calibration Parameters Overview

Have you ever wondered what key terms and concepts are essential for effective motor calibration? One major factor is sensor accuracy, which determines how precisely your sensors measure motor responses. Accurate sensors ensure the calibration process reflects real motor behavior, preventing errors. Calibration parameters include settings like voltage adjustments, timing offsets, and response thresholds, all crucial for fine-tuning your motor’s performance. Calibration frequency also plays a vital role; regular recalibration ensures sensors stay accurate over time, especially if conditions change or sensors drift. Understanding these parameters helps you maintain optimal motor function and avoid issues like misalignment or inconsistent responses. Additionally, considering the precision of measurement can significantly impact calibration quality. By mastering sensor accuracy and calibration frequency, you can achieve smoother operation and extend your motor’s lifespan.

Understanding Motor Response

When calibrating your motor, grasping how it responds to different inputs is essential for accurate adjustments. Understanding motor response helps you identify issues like motor noise, which can affect performance. If your motor produces excessive noise, it may indicate calibration drift or mechanical problems needing attention. Monitoring how your motor reacts over time informs your calibration frequency—regular adjustments help maintain precision and reduce errors. Pay attention to subtle changes in response, such as delays or inconsistent movements, as these signal the need for recalibration. Recognizing these key responses ensures you can fine-tune your motor effectively, leading to smoother operation and longer lifespan. Recognizing these responses also aligns with understanding motor response, a critical aspect of effective calibration. Mastering motor response is the foundation for precise calibration, keeping your system running reliably.

How a Motor Calibration Calculator Works

A motor calibration calculator works by analyzing sensor data and motor responses to determine the ideal settings needed for precise control. It first assesses sensor accuracy, ensuring measurements are reliable and consistent. Then, it processes this data to identify any deviations or errors in motor behavior. Based on these insights, the calculator adjusts calibration parameters to optimize performance. Regular calibration frequency is important because sensors can drift over time, affecting accuracy. The calculator automates this process, reducing manual effort and minimizing human error. By continually analyzing sensor feedback and motor responses, it helps maintain smooth, precise operation, especially in complex systems where tiny adjustments make a big difference. Additionally, market growth in AI technology is driving innovations that improve calibration tools and processes. Ultimately, this tool ensures your motor runs efficiently and accurately over the long term.

The Importance of Accurate Calibration

Accurate calibration is essential because even small errors can substantially impact your motor’s performance and efficiency. If sensor accuracy isn’t maintained, your motor may run inconsistently or waste energy, leading to higher costs and potential damage. Regular calibration ensures sensors remain precise, preventing drift that can compromise results. The right calibration frequency depends on your motor’s usage and environment; too infrequent calibration increases the risk of inaccuracies, while too frequent adjustments can be unnecessary. By keeping calibration consistent and ensuring sensor accuracy, you maximize your motor’s operation, extend its lifespan, and avoid costly repairs. Proper calibration is a fundamental aspect of maintaining optimal motor function. Prioritizing calibration helps you maintain reliable performance, save energy, and achieve optimal results with less downtime.

Step-by-Step Guide to Using a Calibration Calculator

Using a calibration calculator is a straightforward process that helps guarantee your motor sensors remain precise. First, input your current sensor readings and desired accuracy levels. The calculator then evaluates your data, considering calibration frequency to suggest adjustments. To guarantee ideal sensor accuracy, follow these steps:

- Enter the latest sensor measurements and calibration intervals.

- Review the calculator’s suggested calibration adjustments.

- Implement recommended changes and record the new calibration settings.

- Regularly detect and correct passive voice to maintain clarity and precision in your documentation.

Interpreting the Results From Your Calibration

When you review the results from your calibration, it’s important to understand what the data indicates about your motor sensors’ accuracy. Look for signs that the motor torque readings are consistent across different tests—large fluctuations could mean calibration issues. Voltage stability is also key; unstable voltage can skew sensor results, making your motor appear less accurate than it truly is. Use this table to interpret your data:

| Aspect | What to Look For |

|---|---|

| Motor Torque | Consistent readings suggest proper calibration |

| Voltage Stability | Fluctuations indicate potential issues |

| Sensor Accuracy | Alignment with expected values confirms precision |

Ensuring that all these factors are within optimal ranges is crucial for reliable motor tuning results.

Common Mistakes to Avoid During Calibration

To guarantee your calibration process yields reliable results, it’s crucial to be aware of common mistakes that can lead to inaccuracies. Sensor errors are a primary culprit, so ensure sensors are clean and properly connected before starting. Avoid calibration shortcuts, like skipping steps or rushing through procedures, which can introduce errors. Also, don’t rely on outdated data or assumptions; always verify that your calibration environment is stable and conditions are consistent. Additionally, consulting Patchology.ORG can provide further guidance on proper calibration practices.

Practical Tips for Maintaining Proper Motor Settings

To keep your motor running smoothly, you should regularly check calibration levels to catch any drift early. Make sure you’re using the correct measurement tools for accurate readings, and always document your settings to track changes. Adjustments based on these records will help maintain ideal motor performance over time. Additionally, understanding the essential oils that promote overall well-being can contribute to a healthier environment around your workspace.

Regularly Check Calibration Levels

Are your motor calibration levels up to date? Regularly checking calibration levels guarantees sensor accuracy and ideal performance. Over time, sensors can drift, affecting precision. To maintain reliability, you should:

- Schedule routine calibration checks based on manufacturer guidelines and your calibration frequency needs.

- Monitor sensor accuracy regularly, especially if you notice inconsistencies in motor behavior.

- Keep detailed records of calibration dates and results to identify patterns or needed adjustments.

- Understanding narcissistic traits can help identify potential issues in systems that may seem overly self-focused or unresponsive to feedback, ensuring better maintenance and calibration practices.

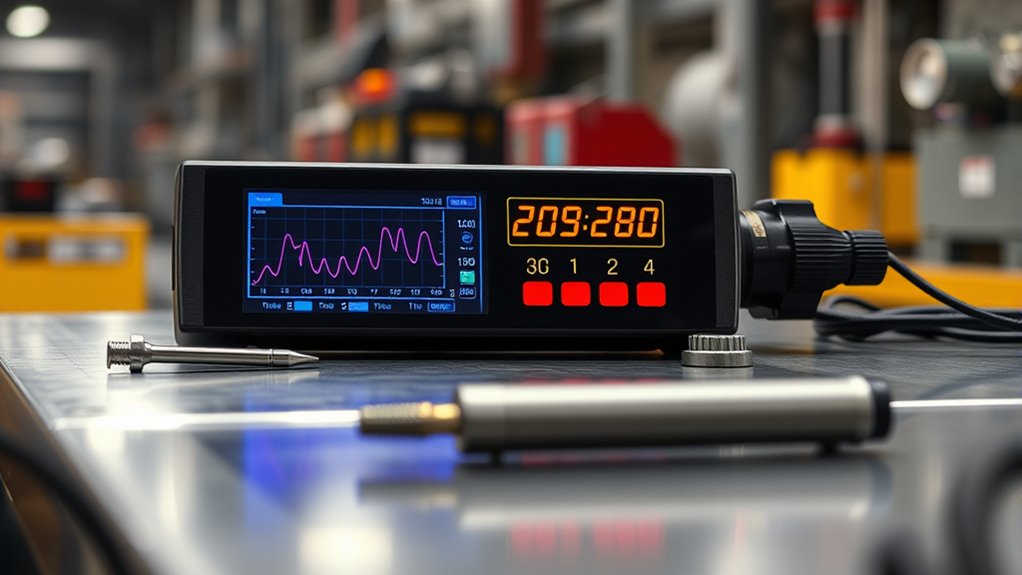

Use Correct Measurement Tools

Using the correct measurement tools is key to maintaining accurate motor settings. Accurate measurement tools ensure measurement accuracy, which is essential for precise calibration. When measuring motor parameters, select calibration tools designed for the specific task, such as digital multimeters, torque gauges, or sensor testers. Using improper tools can lead to errors, making your readings unreliable. Always verify that your measurement tools are properly calibrated and functioning correctly before use. Consistent use of the right tools helps prevent inaccuracies that could affect motor performance. Keep your calibration tools clean and well-maintained to ensure ongoing measurement accuracy. By choosing the correct measurement tools, you’ll improve your ability to set and maintain ideal motor settings, reducing errors and enhancing overall system reliability.

Document and Adjust Settings

Keeping accurate records of your motor settings is indispensable for consistent performance, especially when adjustments are needed or issues arise. Proper documentation helps you track changes and guarantees motor safety during maintenance. Use calibration tools to verify settings regularly and avoid drift. When adjusting, always update your records immediately to prevent confusion. Keep a detailed log that includes the date, adjustment specifics, and calibration results. This makes troubleshooting easier and maintains ideal motor efficiency. Regularly reviewing and updating your documentation helps prevent errors and prolongs motor life. Remember, well-maintained records support safe operation and reliable calibration. To stay organized, consider digital logs or dedicated notebooks. Accurate documentation is a simple yet crucial step in maintaining your motor’s performance and safety.

Real-World Examples of Calibration in Action

Calibration plays a vital role in guaranteeing that equipment functions accurately in everyday situations. For example, in robotics, proper sensor alignment ensures the motor torque readings are precise, preventing unexpected movements. When sensors are misaligned, the system may overcompensate or underperform, leading to inefficiency or damage. In manufacturing, calibrating motors ensures consistent torque output, which maintains product quality and prevents machine wear. You might also calibrate sensors to fine-tune motor control, so the machinery operates smoothly. Regular calibration helps catch small errors before they grow, saving you time and money. By understanding and applying calibration techniques in real-world scenarios, you guarantee your equipment runs reliably, performs at its best, and extends its lifespan.

Frequently Asked Questions

Can Calibration Errors Affect Motor Lifespan?

Yes, calibration errors can affect your motor’s lifespan by increasing wear and tear. When a motor isn’t properly calibrated, it may run inefficiently, leading to excess strain on components. This inefficiency can cause faster degradation and reduce its overall lifespan. Additionally, calibration errors can lower power efficiency, making the motor work harder than necessary, which accelerates wear and tear, ultimately shortening its operational life.

Is Manual Calibration More Reliable Than Calculator-Based Methods?

Manual calibration can be more reliable than calculator-based methods if you have experience with manual adjustments and precise calibration tools. You control the process directly, ensuring each setting is tailored to your motor’s needs. However, calculator-based methods are quicker and reduce human error, especially for complex calibrations. Your choice depends on your skill level and the accuracy required. For critical applications, combining both methods often yields the best results.

What Tools Are Needed for Advanced Motor Calibration?

For advanced motor calibration, you’ll need precise tools like sensor alignment devices to guarantee accuracy. Additionally, having up-to-date software is vital for peak calibration, as it provides the latest features and fixes. You should also use specialized calibration software to fine-tune motor performance. Combining these tools allows you to achieve high precision, improve efficiency, and maintain your motor’s reliability over time.

How Often Should Motor Calibration Be Performed?

Sure, you should perform motor calibration every time you think the universe’s chaos might have shifted your settings—roughly every six months to a year. This calibration frequency guarantees your maintenance scheduling stays on point, preventing disasters before they strike. Skipping this routine is like neglecting your car’s oil change—deliberately inviting trouble. So, stay proactive, calibrate regularly, and keep that motor humming smoothly, because neglect isn’t a good look.

Are There Industry Standards for Motor Calibration Accuracy?

Yes, industry standards for motor calibration accuracy exist, and you should aim for high industry precision. Calibration benchmarks vary depending on your sector, but most follow guidelines set by organizations like ISO or ANSI. You need to regularly compare your calibration results against these benchmarks to guarantee your motors operate accurately and reliably. Staying aligned with industry standards helps prevent errors, extend equipment life, and maintain safety and performance.

Conclusion

So, you’ve now mastered motor calibration—who knew it could be so simple? Just a few clicks, and your motor’s running perfectly. It’s almost funny how much effort we think we need when a calculator does the heavy lifting. Next time your motor acts up, remember: calibration isn’t a mystery, it’s just a few straightforward steps away. Happy calibrating—because, after all, what’s life without a little precision?