2D, 3D, and 4D rollers differ mainly in movement complexity, pattern quality, and customization. 2D rollers create sharp, consistent lines suitable for simple designs, while 3D rollers add textured, dynamic effects for more depth. 4D rollers offer multi-pattern options for intricate, eye-catching visuals. Troubleshooting common issues like uneven coverage or poor adhesion involves cleaning, calibrating, and selecting the right material. Staying aware of signs for replacement will help maintain ideal performance; exploring these details further can improve your results.

Key Takeaways

- 2D rollers create sharp, consistent lines, ideal for simple designs, while 3D and 4D rollers add textured and dynamic patterns for more complex visuals.

- 3D and 4D rollers offer adjustable pressure and movement patterns, enhancing customization and surface compatibility.

- Troubleshooting common issues includes checking calibration, cleaning rollers thoroughly, and ensuring material compatibility for optimal results.

- Regular maintenance like cleaning and inspecting rollers prevents uneven coverage, cracks, or poor paint adhesion.

- Proper technique involves controlled movements, correct roller orientation, and selecting the right roller type based on desired visual effects.

Understanding the Basic Differences Between 2D, 3D, and 4D Rollers

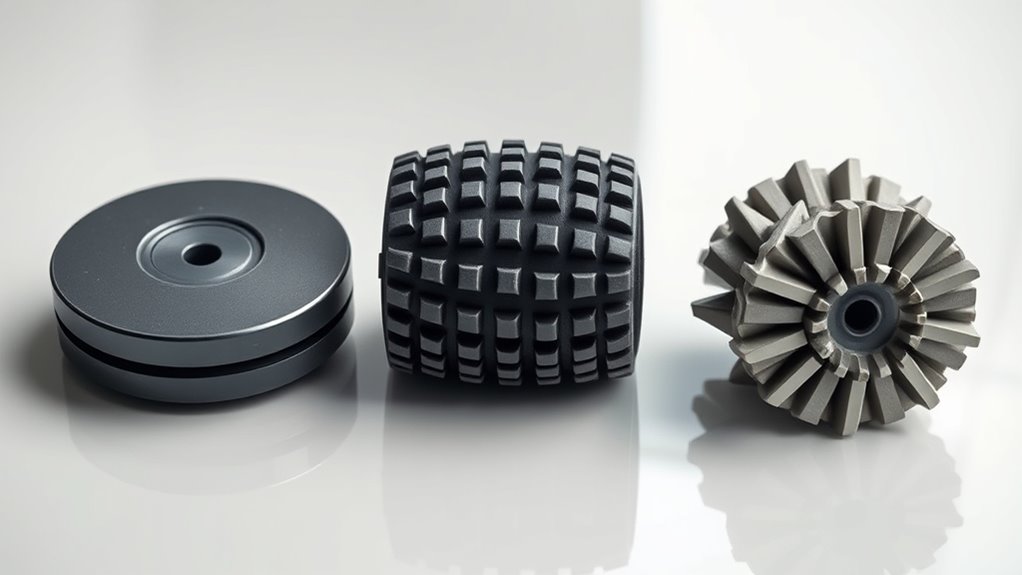

While all three types of rollers—2D, 3D, and 4D—are designed to massage muscles, they differ markedly in how they operate and target tissue. 2D rollers move in two directions, usually back and forth, offering basic compression and relying on material compatibility to suit different skin types. 3D rollers introduce a third axis, providing more dynamic, targeted pressure that penetrates deeper. Their ergonomic design ensures comfort during use and better control. 4D rollers take this further by incorporating multiple movement patterns and adjustable intensity, delivering a highly personalized massage experience. Each type’s construction emphasizes material compatibility and ergonomic design, making them suitable for varying needs and preferences. Understanding these differences helps you choose the right roller for effective, comfortable muscle relief. Additionally, advancements in roller technology often incorporate material compatibility to optimize performance and user comfort.

Key Features and Benefits of Each Roller Type

Each roller type offers unique advantages in visual impact and detailing, allowing you to achieve different artistic effects. You’ll also find varying levels of flexibility and customization, helping you to tailor your work to your specific needs. Understanding these key features helps you choose the right roller for your project’s quality and efficiency. Incorporating AI security measures can further enhance your ability to protect digital assets and optimize your workflow.

Visual Impact and Detailing

Understanding the visual impact and detailing capabilities of different roller types helps you choose the right tool for your project. 2D rollers excel at creating sharp, consistent lines and patterns, making them ideal for precise detailing. They deliver high visual quality with clear, crisp designs that stand out. 3D rollers, on the other hand, offer more textured and dynamic patterns, adding depth and visual interest, though with slightly less detailing precision. 4D rollers combine the strengths of both, providing intricate patterns with enhanced dimensional effects, which can elevate the overall visual impact. Your choice depends on whether you prioritize sharp, detailed visuals or textured, eye-catching designs. Each roller type impacts the final look, so understanding these differences helps you achieve your desired aesthetic effectively.

Flexibility and Customization

The flexibility and customization options of 2D, 3D, and 4D rollers considerably influence how well they adapt to various project needs. 2D rollers typically offer straightforward designs with limited adjustments, making them ideal for consistent, sharp lines where uniformity is key. In contrast, 3D and 4D rollers provide enhanced material compatibility and ergonomic design features, allowing for more complex textures and detailed effects. The choice of roller type can also impact the overall design versatility and efficiency during application.

Common Use Cases for 2D, 3D, and 4D Rollers

2D, 3D, and 4D rollers each serve unique purposes based on their design complexity and targeted applications. If you’re focusing on pattern complexity and texture detail, selecting the right roller is essential.

- Use 2D rollers for simple, flat textures like background effects or basic patterns.

- Opt for 3D rollers when you need more depth and intricate surface patterns, ideal for highlighting texture detail.

- Choose 4D rollers for highly complex, multi-layered designs that demand dynamic pattern variations and depth.

Each roller type helps achieve specific visual effects, making them suitable for different projects. Whether you’re creating minimalist backgrounds or detailed, textured artwork, understanding these common use cases allows you to select the best roller to match your creative goals.

How to Choose the Right Roller for Your Needs

Choosing the right roller depends on your project’s complexity and the visual effects you want to achieve. Consider how much roller customization you need and whether the roller’s material compatibility matches your substrate. For detailed designs, a 3D or 4D roller offers more precision, while 2D rollers suit simpler tasks. Evaluate the surface and material you’ll work with to guarantee compatibility, preventing damage or poor results. Use the table below to match your needs:

| Project Type | Recommended Roller Type | Key Considerations |

|---|---|---|

| Fine detail work | 3D or 4D rollers | High customization, material match |

| Large areas | 2D rollers | Speed, ease of use |

| Durable surfaces | 4D rollers | Material compatibility, durability |

| Repetitive patterns | 3D rollers | Customization options |

Troubleshooting Common Issues With Your Roller

When you encounter issues with your roller, addressing them promptly can guarantee the best results. Common problems include poor paint adhesion, uneven coverage, and calibration errors. To fix these, start by checking your roller’s calibration to verify it’s applying consistent pressure and coverage. If paint isn’t sticking properly, clean the roller thoroughly and confirm the paint consistency. Uneven coverage can often be solved by adjusting your technique or replacing worn-out rollers. Also, inspect for debris or dried paint that could interfere with performance. Regularly calibrating your roller and maintaining proper paint adhesion practices will help prevent these issues. Keep an eye on your equipment, and don’t hesitate to recalibrate or clean your roller for ideal results. For optimal performance, consider using specialized spray tips that are designed for different finishes and surfaces.

Maintenance Tips to Extend the Life of Your Roller

Regular maintenance is key to extending the lifespan of your roller and ensuring consistent performance. Start by regularly performing roller cleaning to remove dust, debris, and product buildup that can hinder smooth operation. Use a gentle cleaner suitable for your roller type and avoid harsh chemicals. Additionally, applying proper lubrication techniques helps reduce friction and prevents wear. Use the recommended lubricants sparingly and focus on moving parts like bearings or joints. Check for signs of dryness or squeaking, which indicate it’s time for lubrication. Keep your roller in a clean, dry environment to prevent rust and dirt accumulation. Regularly inspecting and maintaining your roller with these simple steps will prolong its life and keep it functioning *ideal*. Incorporating noise reduction technology can further enhance your roller’s operation and longevity.

Recognizing When It’s Time to Replace or Upgrade Your Roller

Over time, signs of wear and decreased performance indicate that it’s time to replace or upgrade your roller. You might notice uneven results, persistent discomfort, or difficulty achieving desired effects. Keep an eye out for:

- Faded or limited color options that no longer suit your needs

- Visible damage or worn-out surfaces affecting performance

- Rising pricing considerations, making repairs less economical

- Considering the durability and performance of electric dirt bikes can guide your decision to upgrade or replace your roller.

Upgrading your roller can offer better features and more color choices, enhancing your experience. If your current roller’s performance declines or it’s no longer cost-effective to maintain, it’s a clear sign to think about a replacement. Recognizing these indicators helps you make smarter decisions and ensures you get the most out of your investment.

Tips for Properly Using Your Roller for Maximum Effectiveness

To get the most out of your roller, make sure you’re applying the correct technique for your needs. Regular maintenance, like cleaning and inspecting your roller, helps keep it functioning effectively. Keep these tips in mind to guarantee you’re using your roller safely and efficiently. Additionally, understanding the proper application methods can enhance your skincare routine and optimize results.

Correct Technique Application

Using your roller correctly is essential to maximize its benefits and prevent injury. Proper application techniques ensure you get the most out of your roller, especially during artistic application. Focus on controlled, steady movements to avoid uneven pressure and damage. Keep the roller perpendicular to the surface for consistent coverage. Adjust your pressure based on the type of roller and the material you’re working with. For artistic application, use smooth, continuous motions to create clean lines and textures. Additionally, understanding the best tools for the job can help optimize your results and ensure longevity of your equipment.

- Maintain a consistent speed and pressure to prevent streaks or uneven layers

- Use overlapping passes for even coverage and ideal results

- Experiment with different angles to achieve varied textures and effects

Regular Maintenance Practices

Regular maintenance is essential to keep your roller performing at its best and to extend its lifespan. Start with regular cleaning routines after each use—wipe down the surface and rollers to remove dirt, oils, and debris. This prevents buildup that can impair effectiveness. Proper storage solutions also matter; store your roller in a cool, dry place, away from direct sunlight or extreme temperatures. Use a protective cover if available to prevent dust accumulation. Check for signs of wear or damage periodically and address issues promptly. Keeping your roller clean and stored correctly guarantees smooth operation and longevity. Additionally, monitoring cookie categories can help ensure your browsing experience remains secure and efficient while using your device. Keeping your roller well-maintained and aware of online privacy practices maximizes your overall experience and helps you avoid unnecessary repairs or replacements down the line.

Safety Precautions and Best Practices During Use

Ensuring safety during roller use is essential to prevent injuries and maximize the benefits of your workout. Always wear protective gear, such as knee pads and wrist supports, to protect yourself from falls or slips. Use your rollers in a safe environment—clear the area of obstacles and ensure good lighting to avoid accidents. Maintain proper posture and control your movements, especially with 3D and 4D rollers, to prevent strain or injury. Keep a steady pace and listen to your body’s signals. Additionally, warm up before starting and stay mindful of your surroundings to avoid collisions. Understanding the importance of high contrast ratios in projectors can also help you create a safer and more visually effective environment. With these precautions, you’ll enjoy a safer, more effective roller experience. Remember, safety always comes first.

Frequently Encountered Problems and How to Resolve Them

Despite following safety precautions, you might still encounter common issues with 2D, 3D, or 4D rollers. Material compatibility can be a problem—using a roller not suited for your skin type or surface may cause discomfort or damage. Additionally, brand comparison reveals that some brands offer better durability or softer textures, reducing problems like skin irritation or uneven rolling.

| Issue | Solution |

|---|---|

| Material not compatible | Choose rollers designed for your skin or surface type. |

| Uneven rolling | Check for debris or damage, replace if necessary. |

| Excessive pain | Use softer rollers and adjust pressure. |

| Cracks or splits | Opt for high-quality, durable brands. |

| Poor performance | Compare brand reviews and select reputable options. |

Frequently Asked Questions

Can 2D, 3D, and 4D Rollers Be Used Interchangeably?

You can’t really use 2D, 3D, and 4D rollers interchangeably due to compatibility issues. Each type is designed for specific applications, and their size or shape may not fit your device or project properly. Interchangeability concerns can lead to ineffective results or damage. Always check your roller’s specifications and compatibility before switching between types, ensuring you get the best performance without risking damage.

Are There Specific Safety Gear Recommendations for Each Roller Type?

You should always wear appropriate safety gear and protective equipment when using any roller type. For 2D rollers, goggles and gloves protect your eyes and hands from debris. 3D and 4D rollers may require ear protection due to noise, along with masks to prevent inhaling dust. Visualize yourself fully protected, reducing risk and ensuring a safe, effective workout. Always follow manufacturer recommendations for specific safety gear for each roller type.

How Do Environmental Conditions Affect Roller Performance?

Environmental conditions considerably influence roller performance. Humidity, dust, and temperature fluctuations can cause wear and affect the roller’s smooth operation. You should regularly monitor environmental impact and perform maintenance considerations like cleaning and lubrication to guarantee ideal performance. For outdoor use, choose rollers with weather-resistant features, and indoors, maintain a controlled environment to reduce debris buildup and extend the roller’s lifespan. Proper care minimizes downtime and enhances efficiency.

What Are the Signs of Excessive Wear in Each Roller Type?

Like a worn-out map guiding your journey, excessive wear shows through dulled roller surfaces and increased bearing noise. In 2D rollers, look for surface scratches or flattening, while 3D and 4D rollers might exhibit uneven textures or ridges. Listen for unusual sounds—bearing noise often signals internal damage. If you notice these signs, it’s time to inspect and replace the rollers to keep your equipment running smoothly.

Can Rollers Be Customized for Specialized Applications?

Yes, you can customize rollers for specialized applications. Most manufacturers offer a range of customization options, including material selection, surface texture, diameter, and core design. By tailoring these features, you guarantee the rollers meet your specific needs, whether for delicate materials or high-pressure environments. Customization enhances performance, durability, and efficiency, making your equipment more reliable and suited to your unique operational requirements.

Conclusion

Choosing the right roller can transform your recovery routine. For instance, if you frequently target deep muscle knots, a 3D roller might be your best bet. Remember, regular maintenance and proper use guarantee longevity and effectiveness. By understanding the differences and troubleshooting common issues, you’ll get the most out of your roller. With a little care, you’ll experience relief and improved mobility—making your sessions more productive and enjoyable.