To plan effective pressure relief mechanics, you need to select the right device type—spring-loaded valves, rupture disks, or pilot-operated relief valves—based on your system’s pressure, flow, and safety requirements. Proper sizing is vital to prevent under- or over-venting, and it involves understanding the maximum expected conditions. Make certain of compliance with safety standards, integrate relief devices seamlessly with control systems, and maintain detailed documentation. If you keep these factors in mind, you’ll be prepared to develop a reliable and safe relief system.

Key Takeaways

- Different types of relief devices include spring-loaded valves, rupture disks, and pilot-operated valves, each suited for specific scenarios.

- Proper sizing relies on maximum pressure, flow conditions, vessel volume, and process parameters, guided by established standards.

- Integration with control systems and safety protocols ensures relief devices activate correctly during abnormal conditions.

- Regular inspection, calibration, and documentation are essential for system reliability, compliance, and effective troubleshooting.

- Understanding operating conditions and potential failure modes helps prevent system overloads and enhances safety measures.

What Are the Main Types of Pressure Relief Devices and How Do They Differ?

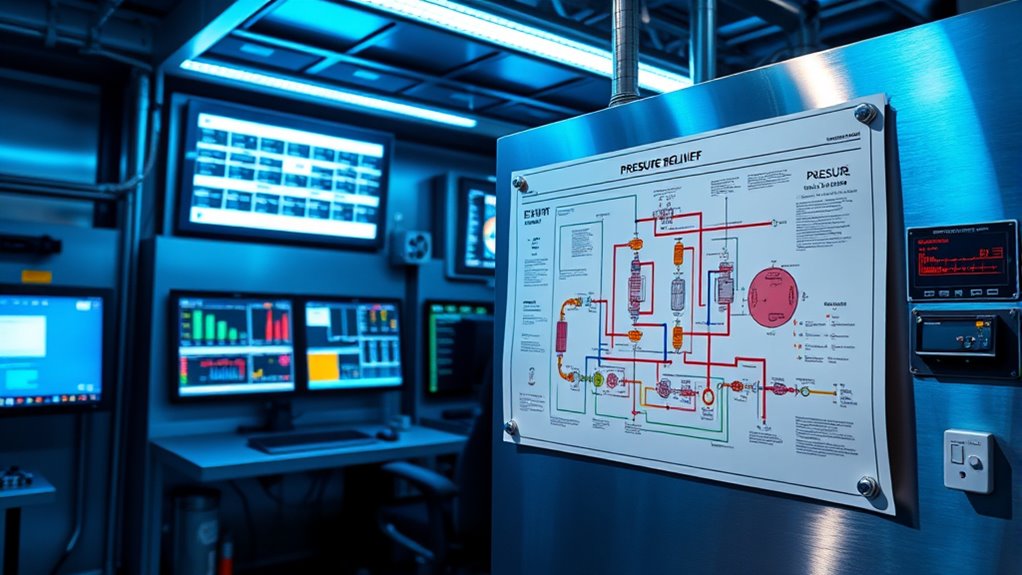

Have you ever wondered how pressure relief devices guarantee safety in industrial systems? The answer lies in the various pressure relief types designed for specific applications. Common device differences include their operation mechanisms, such as spring-loaded valves, rupture disks, and pilot-operated relief valves. Spring-loaded relief valves are the most versatile, opening when pressure exceeds a set point. Rupture disks, on the other hand, act as a one-time safety barrier that bursts under high pressure. Pilot-operated relief valves utilize a control pilot to open more precisely, ideal for sensitive systems. Each type has unique advantages, making them suitable for different scenarios. Understanding these pressure relief types ensures you select the right device to protect your equipment and personnel effectively.

How Do I Determine the Appropriate Sizing for Pressure Relief Valves?

Determining the appropriate sizing for pressure relief valves is crucial to guarantee they operate effectively without causing unnecessary system shutdowns or safety hazards. To do this, you need to assess the maximum expected pressure and flow conditions of your pressure vessel. Relief sizing involves calculating the flow capacity needed to vent excess pressure safely, ensuring the valve can handle the maximum relief load. You’ll also consider factors like the vessel’s volume, fluid properties, and process conditions. Proper relief sizing prevents under- or over-venting, which can compromise safety or cause equipment issues. Using established standards and formulas helps you select a valve with the right capacity. Accurate sizing ensures your pressure relief system responds reliably during overpressure events, maintaining safety and system integrity. Additionally, understanding the potential pitfalls of new pressure relief technologies can help you avoid operational disruptions and security vulnerabilities.

What Safety Standards Should Be Considered When Designing Relief Systems?

When designing relief systems, adhering to established safety standards is essential to guarantee reliable protection against overpressure events. Key standards include pressure vessel codes, which set the requirements for design, material, and construction to promote safety. Additionally, safety inspections are critical to verify compliance and identify potential issues before operation. Implementing self watering plant pots standards can help ensure that the system maintains consistent and safe operation under various conditions. Consider these standards: 1. Follow pressure vessel codes relevant to your jurisdiction to ensure legal compliance and safety. 2. Conduct regular safety inspections to maintain system integrity and detect wear or damage early. 3. Implement standards for relief valve testing and maintenance to guarantee proper operation during emergencies. Incorporating these standards helps prevent failures, protect personnel, and minimize environmental risks.

How Can I Accurately Assess Pressure and Temperature Conditions for Relief Planning?

Accurately evaluating pressure and temperature conditions is vital for designing effective relief systems. To do this, you need reliable pressure monitoring methods that provide real-time data, helping you identify maximum and normal operating pressures. Consistent temperature measurement is equally important, as it influences material selection and relief device settings. Use calibrated instruments and multiple measurement points to capture accurate conditions across your system. Additionally, review historical data, process flow diagrams, and safety margins to understand potential variations. Regularly calibrate your sensors and verify readings to guarantee accuracy. Incorporating pressure sensor calibration into your routine ensures the reliability of your measurements. This thorough approach allows you to determine the true operating envelope of your equipment, ensuring your relief system is appropriately designed to protect against overpressure and thermal hazards.

What Are Common Causes of Relief System Failures and How Can They Be Prevented?

Relief system failures often stem from overlooked design flaws, improper maintenance, or operating conditions that exceed specifications. To prevent these issues, focus on three key areas:

Prevent relief system failures by addressing design flaws, maintenance, and operating conditions proactively.

- Regular inspections and maintenance to catch corrosion issues early, ensuring components remain functional.

- Proper operator training so you understand system limits and respond quickly to pressure anomalies.

- Ensuring operating conditions stay within design parameters, avoiding sudden pressure surges or extreme environments that can overload the relief system.

- Incorporating high-quality materials in system components can significantly reduce the risk of corrosion and mechanical failure over time.

Corrosion issues weaken system components over time, increasing failure risk. Operator training helps you identify signs of system stress and maintain proper procedures. By addressing these factors proactively, you minimize the chance of relief system failures and improve overall safety.

How Do I Select the Right Materials for Relief System Components?

Choosing the right materials for relief system components is essential to guarantee durability, safety, and reliable performance under various operating conditions. During material selection, focus on factors like temperature, pressure, and chemical exposure to ensure the components withstand operational stresses. Prioritize corrosion resistance to prevent degradation over time, especially if the system handles corrosive fluids or environments. Metal alloys, such as stainless steel or bronze, often offer excellent corrosion resistance and strength, making them suitable choices. For specific applications, consider non-metallic materials like certain plastics or composites that resist corrosion and are lightweight. Additionally, implementing practical support measures, such as regular inspections and maintenance, can help prolong the lifespan of relief system components. Ultimately, selecting materials with proven durability and corrosion resistance ensures your relief system functions reliably, minimizes maintenance, and maintains safety standards throughout its service life.

What Maintenance and Testing Procedures Are Necessary to Ensure System Reliability?

Regular maintenance and testing are essential to keep relief system components functioning properly over time. To guarantee reliability, you should focus on these key procedures:

- Perform regular sensor calibration to maintain accurate pressure readings.

- Conduct corrosion monitoring to detect early signs of material degradation.

- Test safety devices and valves periodically to verify proper operation and responsiveness.

- Incorporate industry trends to stay informed about evolving best practices and technologies in pressure relief systems.

How Should Relief Systems Be Integrated With Control and Safety Systems?

To guarantee the relief system functions effectively within your facility, you need to integrate it seamlessly with your control and safety systems. Proper relief system integration ensures that pressure relief devices activate promptly during abnormal conditions, preventing equipment damage or hazards. You should establish clear control safety coordination by aligning shutdown signals, alarms, and relief actuation. Use interlocks and communication protocols to ensure that safety systems override control systems when needed, avoiding conflicting actions. Regularly review and test the integration points to confirm proper operation under different scenarios. Document all integration procedures and responses to maintain compliance and facilitate troubleshooting. Effective control safety coordination minimizes risks, enhances system reliability, and ensures your relief system performs as intended during critical events. Additionally, understanding the importance of attention in creative practice can help teams stay focused and responsive during complex safety integrations.

What Documentation and Records Are Essential for Compliance and Troubleshooting?

Maintaining accurate and thorough documentation is crucial for ensuring compliance with regulations and facilitating effective troubleshooting. Proper documentation records help you verify system performance, identify issues quickly, and meet regulatory requirements. Essential documentation includes:

- Inspection and maintenance logs that track system checks and repairs.

- Calibration records for pressure relief devices to ensure accuracy.

- Incident reports documenting any malfunctions or safety events.

These records support compliance troubleshooting by providing a clear history of system performance and maintenance activities. Keeping detailed documentation ensures you can quickly pinpoint problems, demonstrate regulatory adherence, and implement corrective actions efficiently. Regularly updating and reviewing your documentation records keeps your pressure relief system aligned with safety standards and operational best practices. Additionally, maintaining detailed records of spoilage signs helps in identifying and preventing potential failures before they escalate.

Frequently Asked Questions

How Do Environmental Factors Influence Relief System Design?

Environmental impacts play a vital role in your relief system design by affecting material choices and installation methods. You need to take into account factors like temperature, humidity, and corrosive elements that could compromise system integrity. Additionally, regulatory compliance is essential, so you must adhere to environmental standards and safety codes. By accounting for these environmental factors, you guarantee your relief system is safe, effective, and compliant with all applicable regulations.

What Are the Latest Innovations in Pressure Relief Technology?

Imagine a world where safety is seamless; that’s what latest pressure relief tech offers. You’ll find advanced pressure sensors that precisely detect fluctuations, enabling real-time valve optimization. These innovations reduce false alarms and improve response times. Smart systems now adapt automatically, ensuring safer operations while minimizing downtime. Embracing these developments means you’re at the forefront of safety technology, making your pressure relief systems smarter, more reliable, and more efficient than ever before.

How Does System Scaling Affect Relief Device Selection?

System scaling impacts relief device selection because scaling challenges demand careful capacity adjustments. As your system grows or changes, you must guarantee the relief device can handle increased or decreased pressure loads without failing. Failing to account for these adjustments could lead to inadequate protection or unnecessary maintenance. Always evaluate how scaling affects your system’s flow rates and pressure requirements, then select a relief device that accommodates these capacity adjustments effectively.

What Training Is Recommended for Personnel Managing Relief Systems?

Think of your team as the guardians of safety, and proper training is your shield. You should pursue thorough courses on relief system maintenance, emergency response, and safety protocols. Hands-on workshops and regular refresher sessions ensure your personnel stay sharp, reducing risks and ensuring personnel safety. Staying updated on industry standards and best practices makes your team confident and capable, turning potential hazards into manageable risks.

How Can Digital Twins Improve Relief System Planning Accuracy?

A digital twin can substantially improve relief system planning accuracy by providing a virtual replica of your relief system. You can simulate different scenarios, identify potential issues early, and optimize system performance before implementation. This real-time, data-driven approach helps you make informed decisions, reduces errors, and guarantees your relief system operates safely and efficiently under various conditions. Digital twins are essential tools for proactive, precise relief system management.

Conclusion

By understanding the different relief devices, sizing correctly, and following safety standards, you set yourself up for success. Regular maintenance, proper material selection, and thorough documentation keep your system reliable and compliant. Don’t put all your eggs in one basket—plan carefully and stay vigilant. When you approach relief system planning with attention to detail, you’ll avoid future headaches and keep things running smoothly. Remember, an ounce of prevention is worth a pound of cure.