To troubleshoot space-saving recline geometry effectively, start by inspecting for common issues like misaligned hinges, loose bolts, or improper cable tension. Use tools like a torque wrench or digital caliper to measure and adjust components precisely. Clean and lubricate the mechanism regularly and tweak tension settings gradually. If problems persist, attend to wear or damage early, or consider professional help. Keep at it, and you’ll uncover the key steps to restore smooth recline function.

Key Takeaways

- Verify cable tension and alignment to ensure smooth recline movement.

- Use torque wrench and calipers to measure and adjust hinge pivot points accurately.

- Clean and lubricate recline components regularly to prevent stiffness and debris buildup.

- Gradually adjust tension screws and test recline angle after each modification.

- Seek professional repair if persistent issues like uneven movement or noise occur.

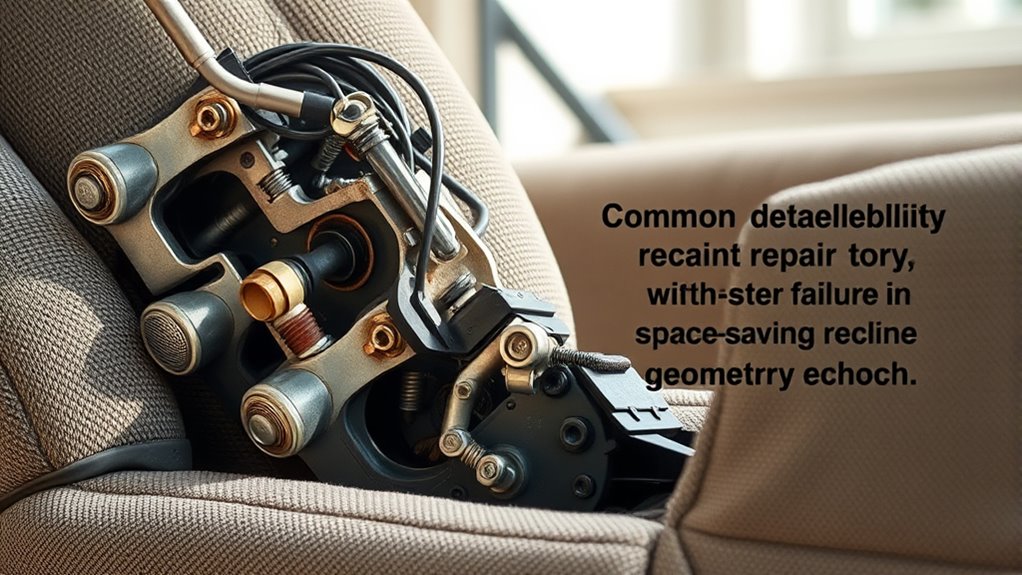

Identifying Common Recline Mechanism Failures

When troubleshooting recline mechanisms, recognizing the most common failures that can disrupt smooth operation is vital. One frequent issue is improper cable adjustments, which can cause the recline to be too stiff or too loose. If the cable isn’t tensioned correctly, the mechanism won’t move smoothly, leading to frustration. Another common failure is hinge misalignment, which can cause uneven movement or sticking points. When hinges aren’t aligned properly, the recline action becomes jerky or unresponsive. Additionally, understanding eye patch benefits can help inform maintenance routines by identifying components that may require more gentle handling or targeted repairs. By inspecting these elements first, you can quickly identify if the problem stems from misadjusted cables or misaligned hinges. Addressing these issues often restores proper function, saving you time and effort during the troubleshooting process.

Tools and Techniques for Effective Troubleshooting

To troubleshoot recline mechanisms effectively, having the right tools and techniques on hand can make all the difference. First, use a torque wrench for force testing to measure the resistance of the recline components. Second, perform manual calibration by adjusting tension settings to restore proper function. Third, employ a set of screwdrivers and Allen wrenches to tighten or loosen critical parts. Fourth, utilize a digital caliper for precise measurements of pivot points and alignment. These techniques help identify whether parts are worn or misaligned. Force testing reveals if the mechanism resists movement properly, while manual calibration ensures the recline angle adjusts smoothly. Additionally, understanding the air purifier maintenance dos and don’ts can help prevent issues caused by dust or humidity affecting the recline mechanism. Combining these tools allows you to diagnose issues quickly and accurately, saving time and preventing unnecessary replacements.

Step-by-Step Guide to Adjusting Recline Geometry

Adjusting recline geometry involves a systematic approach to guarantee smooth and secure operation. First, check for cushion compression issues that may affect recline movement; if the cushion feels overly compressed, consider adjusting the tension or support. Next, examine the mechanism for any signs of dirt or debris, then apply mechanism lubrication to ensure smooth motion. Loosen or tighten the adjustment screws gradually, testing the recline angle after each change. Pay close attention to the reclining angle and ensure the mechanism locks securely in place. If the recline feels stiff or unresponsive, reapply lubrication to critical parts. Always recheck cushion compression and mechanism function after adjustments. Properly calibrated recline geometry results in effortless, reliable operation and prolongs the lifespan of your chair. Being aware of regional resources and tools, such as local repair specialists, can also be beneficial if further adjustments are needed.

Preventative Measures to Maintain Recline Functionality

Regular maintenance is key to keeping your recline mechanism functioning smoothly over time. To guarantee recline preservation, follow these maintenance tips:

Maintaining your recline mechanism ensures smooth operation and longevity.

- Regularly inspect the recline components for signs of wear or damage.

- Lubricate moving parts with appropriate lubricants to prevent stiffness.

- Tighten loose bolts or screws promptly to avoid misalignment.

- Keep the mechanism clean and free of dust and debris that can hinder movement.

- Ensure the mechanism maintains proper alignment to prevent uneven wear and maintain optimal function.

When to Seek Professional Repairs or Replacements

Even with proper maintenance, there comes a point when your recline mechanism may stop functioning correctly. If you notice persistent issues that disrupt your leisure comfort or compromise the ergonomic design of your chair, it’s time to seek professional repairs or consider replacements. Signs include unusual noises, difficulty adjusting the recline, or uneven movement. Ignoring these problems can lead to further damage or reduced support. When repairs are needed, a professional can diagnose and fix complex geometry issues safely and effectively. If the recline functionality remains unreliable despite troubleshooting, replacing the chair might be the best option for maintaining ideal ergonomic support. Prioritize professional help when comfort and proper support are at stake to ensure your space-saving recliner continues serving you well. Understanding sound vibrations and their impact on health can also help in choosing the right repair techniques or therapeutic solutions.

Frequently Asked Questions

How Long Does a Typical Recline Mechanism Repair Take?

A typical recline mechanism repair takes about one to three hours, depending on the extent of recline mechanism maintenance needed. You’ll want to take into account ergonomic design considerations to ensure smooth operation afterward. If you’re comfortable with basic tools, you might do it yourself, but for complex repairs, it’s better to hire a professional. Proper troubleshooting helps prevent future issues and keeps your recline feature working efficiently.

Are There Eco-Friendly Options for Replacing Recline Components?

Yes, you can find eco-friendly options for replacing recline components. Look for parts made from sustainable materials, such as recycled plastics or responsibly sourced wood. Many manufacturers participate in recycling programs, ensuring old parts are properly recycled. By choosing these options, you help reduce waste and support environmental sustainability. Always ask suppliers about their eco-friendly practices to make sure you’re making the most sustainable choice for your recline mechanism replacements.

Can Recline Issues Be Fixed Without Professional Tools?

Did you know that over 60% of recline issues can be fixed with simple DIY fixes? You don’t need professional tools for a tool-free repair. Many recline problems, like stuck or loose mechanisms, can be resolved by adjusting or lubricating parts with basic household items. With patience, you can restore your recline function yourself, saving money and time without needing specialized tools or expertise.

What Are Signs of Early Recline Mechanism Wear?

You’ll notice early signs of recline mechanism wear if you hear squeaking during adjustment or see an uneven recline angle. These issues often indicate that parts are starting to loosen or wear out. You might also feel resistance or difficulty when reclining. Addressing these signs early can prevent further damage, and sometimes simple lubrication or tightening can fix the problem without needing professional tools.

How Does Weight Distribution Affect Recline Performance?

Your weight distribution directly impacts recline performance by influencing the balance point of the mechanism. When you sit unevenly, the load impact on one side increases, causing the recline to feel stiff or unresponsive. To guarantee smooth operation, keep your weight centered and balanced. Proper weight distribution helps maintain ideal balance point, reducing wear and tear, and improving the overall functionality of your recline mechanism.

Conclusion

Think of your recline mechanism as the heartbeat of your chair—when it falters, comfort fades. By understanding its rhythm through proper troubleshooting and care, you keep it pulsating smoothly. Regular maintenance acts as the steady drumbeat, preventing breakdowns. When issues arise beyond your reach, don’t hesitate to call in a pro; sometimes, a gentle touch restores harmony. With attentive care, your recline’s symphony plays on, inviting relaxation whenever you need it.