To properly calibrate your motor, you must calculate its power needs, load torque, and inertia to make certain you select the right size. You need to determine the correct operational speed, voltage, and current parameters to optimize performance. Analyzing power factor, efficiency, and power losses helps improve energy use. Setting up accurate sensors and reviewing data are essential steps. Keep these calculations in mind—more details will guide your calibration process effectively.

Key Takeaways

- Calculate motor power needs based on system demands, battery capacity, and cooling requirements to ensure reliable operation.

- Determine load torque and inertia accurately to select a motor that handles operational forces without overload.

- Establish correct speed ranges and electrical parameters like voltage and current for safe and efficient calibration.

- Measure power factor and efficiency to identify energy losses and optimize motor performance.

- Properly set up calibration equipment, analyze data, and document results to maintain calibration accuracy and system integrity.

Understanding Motor Power Requirements

Have you ever wondered how to determine the right motor power for your application? It starts with understanding your system’s power demands. The key factors include battery capacity, which influences how much energy your motor can draw over time, and the motor’s cooling requirements. A motor running at high power generates more heat, so proper cooling is essential to prevent overheating and ensure longevity. If your application requires frequent or sustained operation, you’ll need a motor with sufficient power output and effective cooling solutions. Additionally, consider how much energy your battery can supply continuously. Matching your motor’s power needs with your battery capacity and cooling setup ensures reliable performance without risking damage or downtime. AI security considerations can also play a role in safeguarding your motor control systems from cyber threats, especially in connected or automated environments.

Calculating Load Torque and Inertia

Calculating load torque and inertia is essential for selecting and sizing your motor accurately. To perform a torque calculation, you need to understand the forces acting on your system during operation, including starting and running conditions. Inertia estimation helps determine how much resistance your load offers to changes in motion, impacting acceleration and deceleration times. By accurately estimating the inertia, you can select a motor capable of delivering the required torque without overloading. Use detailed measurements of your load’s mass and geometry, along with operational parameters, to refine your calculations. Properly evaluating load torque and inertia ensures your motor can handle the demands of your application efficiently and reliably, avoiding potential system failures or performance issues caused by under- or over-sized components. Additionally, understanding the contrast ratio of your projector can significantly affect the perceived sharpness and detail in your images.

Determining the Correct Calibration Speed

To determine the correct calibration speed, you need to establish your desired speed range first. Then, measure how the vehicle performs at different speeds to see where it operates most efficiently. Don’t forget to adjust for load variations to make certain of accurate calibration across all conditions. Incorporating insights from performance optimization can further enhance calibration accuracy.

Establish Desired Speed Range

Before you begin calibrating your motor, it’s essential to determine the appropriate speed range for your application. Establishing a clear desired speed range helps ensure effective speed regulation and prevents overloading or underperforming. Consider the operational requirements and safety protocols to set realistic targets. Think about the maximum safe speed and the minimum needed for reliable performance. This range guides your calibration process, allowing you to fine-tune the motor accurately. By defining these limits early, you reduce the risk of damage and improve overall efficiency. Remember, setting precise speed boundaries is key to achieving outstanding performance while maintaining safety standards. Taking this step ensures your calibration aligns with both technical needs and safety considerations. Additionally, understanding calibration accuracy can help optimize your motor’s performance and longevity.

Measure Vehicle Performance

Measuring vehicle performance is essential for determining the correct calibration speed, as it provides real-world data on how your motor behaves under load. During testing, monitor how different battery chemistry types affect power output, noting any voltage drops or fluctuations. Keep an eye on motor cooling efficiency; if the motor heats excessively during operation, it indicates that you may need to adjust your calibration to prevent overheating. Recording the vehicle’s speed at various throttle points helps establish a reliable performance baseline. By analyzing these metrics, you can fine-tune your motor settings to achieve maximum speed without risking damage. Accurate measurement ensures your calibration reflects real-world conditions, leading to safer, more efficient vehicle operation. Additionally, understanding effective cooling techniques can prevent motor overheating and prolong component lifespan.

Adjust for Load Variations

When adjusting for load variations, it’s important to recognize how different driving conditions impact your motor’s performance. The load impact on your vehicle can alter the required calibration speed, especially as weight distribution shifts with cargo or passenger placement. Heavier loads increase resistance, meaning you need to adjust your motor’s calibration to guarantee ideal operation under these conditions. Consider how uneven weight distribution can cause inconsistent load impact, affecting acceleration and braking responses. To determine the correct calibration speed, test your vehicle with varying loads, noting how each affects performance. By accounting for load impact and weight distribution, you guarantee your motor functions accurately across different load scenarios, maintaining safety and efficiency. Additionally, understanding ONE2CRYPTO market trends can provide insights into optimal adjustment strategies under changing economic conditions.

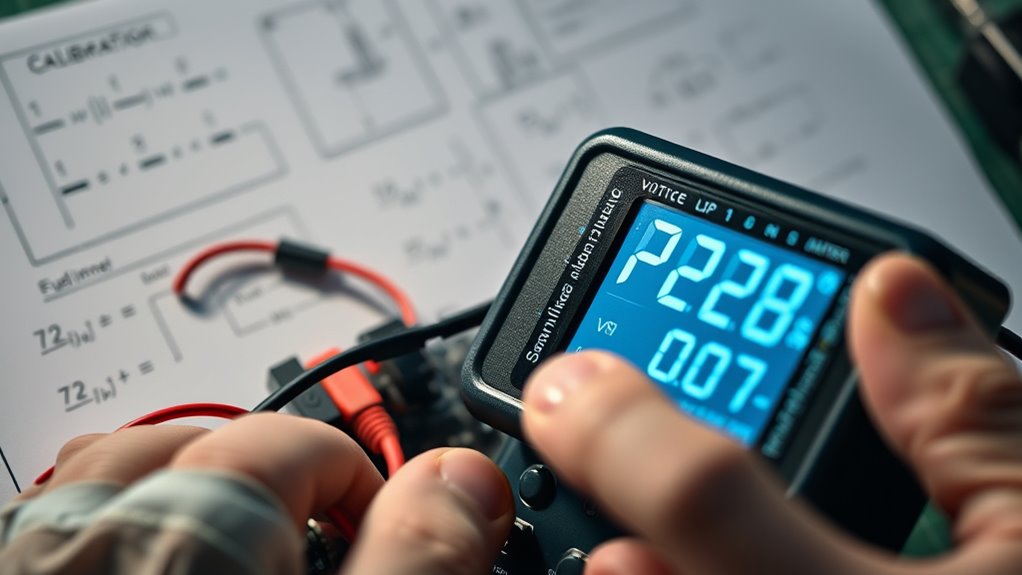

Establishing Voltage and Current Parameters

To accurately calibrate a motor, you need to establish the correct voltage and current parameters, as these directly influence performance and safety. Guaranteeing voltage stability helps prevent fluctuations that could cause overheating or inconsistent operation. Proper current regulation maintains ideal torque without overloading the motor. Focus on setting voltage levels within manufacturer specifications and monitoring current draw during operation. This helps in maintaining optimal performance and preventing damage. Use reliable meters to monitor real-time voltage and current.

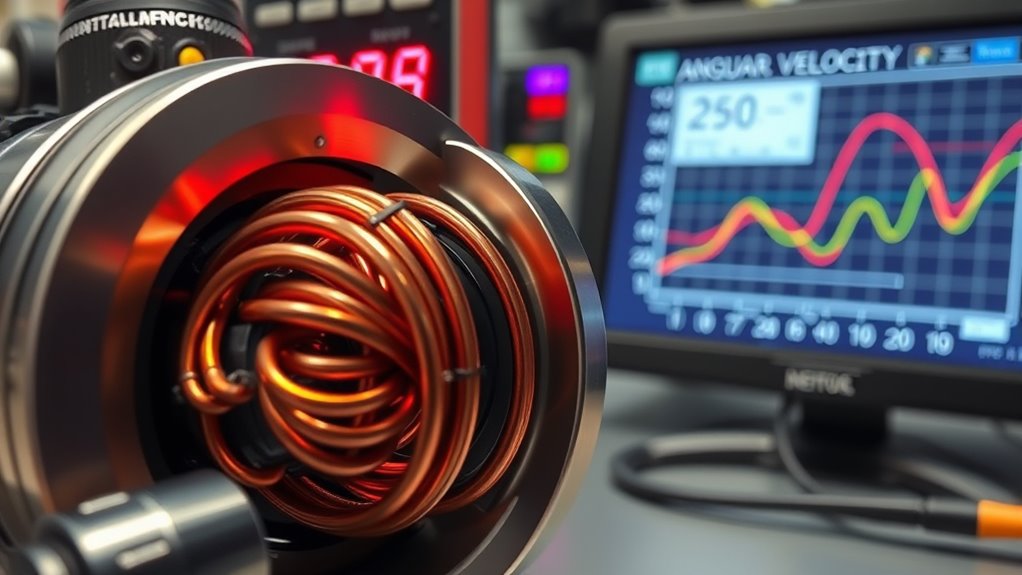

Measuring and Analyzing Power Factor

Have you ever wondered how effectively your motor converts electrical energy into mechanical work? Measuring and analyzing power factor helps you understand this efficiency. Power factor indicates how well your motor uses electrical power, reflecting the ratio of real power to apparent power. A low power factor suggests high reactive power, which doesn’t perform useful work but increases energy costs. To assess it, you’ll need specialized instruments like power analyzers or clamp meters that measure voltage, current, and phase angle. Analyzing these readings reveals the reactive power component and highlights potential inefficiencies. Improving power factor reduces electrical waste, lowers utility bills, and prevents equipment stress. Regularly measuring and analyzing your motor’s power factor is essential for ideal operation and energy savings. Additionally, understanding the characteristics of Honda Tuning can guide you in optimizing your vehicle’s performance and efficiency.

Computing Efficiency and Losses

Understanding how to compute efficiency and losses helps you optimize motor performance. You’ll examine power loss factors that affect overall efficiency and learn methods to accurately calculate them. This knowledge allows you to identify areas where energy is wasted and improve your motor’s operation. Utilizing specific techniques for loss assessment can further enhance your ability to maintain optimal efficiency levels.

Power Loss Factors

Power losses in motors occur because no machine operates with perfect efficiency; some energy is always converted into heat, noise, or other forms of waste. These thermal effects increase with load and environmental influences such as ambient temperature. Understanding power loss factors helps you optimize efficiency and reduce waste. Additionally, diverse design options can influence how effectively a motor manages heat dissipation and energy efficiency.

Efficiency Calculation Methods

Calculating motor efficiency involves determining the ratio of useful output power to the total input power, accounting for all losses that occur during operation. To do this accurately, you need to evaluate factors like motor temperature, which affects efficiency by increasing thermal losses when it rises. Monitoring temperature helps identify when losses spike, guiding cooling or maintenance. Noise reduction is also an indicator; excessive noise often signals inefficiencies or mechanical issues, impacting overall performance. By measuring input and output power carefully and considering how temperature and noise levels fluctuate under load, you can compute efficiency precisely. This approach ensures you understand where energy is lost and how to optimize your motor’s performance, leading to better calibration and longer equipment life.

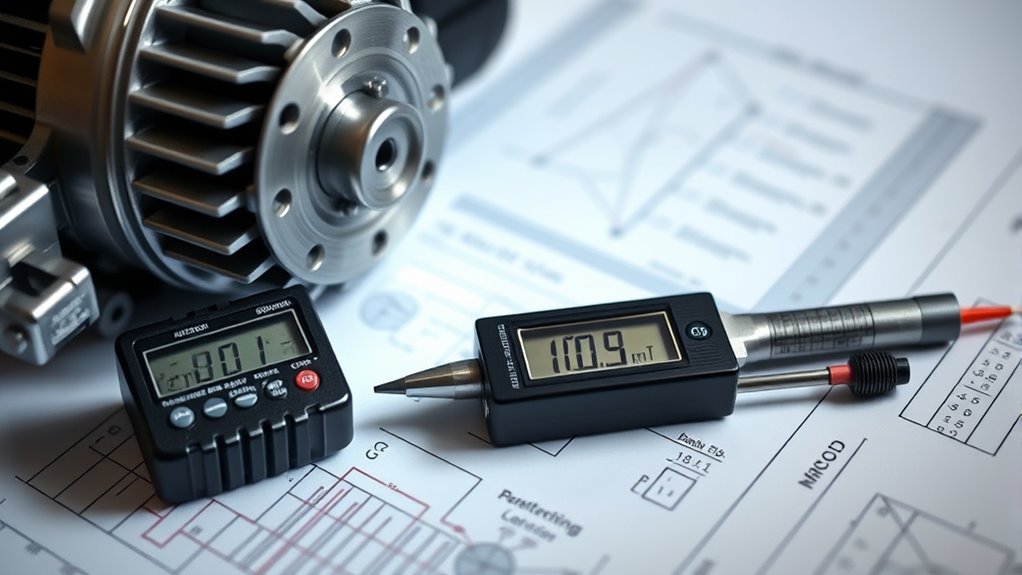

Setting Up Calibration Equipment and Sensors

Before you begin calibrating your motor, it’s essential to properly set up your calibration equipment and sensors. Correct sensor placement guarantees accurate data collection, so position sensors where they can best detect motor movements without interference. Regular equipment calibration guarantees your devices provide reliable readings, preventing errors in your calibration process. To set up effectively, consider these steps:

- Verify sensor placement for ideal accuracy and minimal noise

- Calibrate equipment according to manufacturer instructions

- Secure sensors and devices to prevent movement during testing

Taking these precautions helps ensure your measurements are precise, leading to a more accurate motor calibration. Proper setup minimizes errors and saves you time in the long run, making your calibration process smoother and more reliable.

Analyzing Data and Adjusting Calibration Settings

Once your calibration equipment is properly set up, focus on analyzing the data collected from your sensors. During motor testing, review the sensor calibration results carefully to identify any inconsistencies or deviations. Look for patterns indicating that the motor’s performance isn’t aligned with expected parameters. Use this data to fine-tune your calibration settings, ensuring accurate measurements and smooth operation. If you notice discrepancies, adjust sensor sensitivities or calibration points accordingly. Remember, precise data analysis helps you pinpoint issues early, preventing larger problems later. Confirm your adjustments by rerunning tests and comparing new results with previous data. This iterative process improves calibration accuracy, ensuring your motor functions reliably within ideal parameters. Always base your adjustments on solid data, not assumptions.

Documenting Calibration Results and Maintaining Records

Keeping accurate records of your calibration results is essential for tracking your motor’s performance over time. Proper record keeping guarantees you can identify trends, verify compliance, and troubleshoot issues efficiently. Effective calibration documentation helps maintain consistency and accountability in your calibration process. To optimize your record keeping, consider these key practices:

- Clearly label each calibration report with date, technician, and equipment details

- Store records securely, either digitally or physically, for easy retrieval

- Regularly review and update calibration logs to spot discrepancies or patterns

Frequently Asked Questions

How Often Should Motor Calibration Be Performed for Optimal Performance?

You should perform motor calibration regularly, typically every 6 to 12 months, depending on your equipment’s usage and environment. Calibration frequency is vital for peak performance, so include it in your maintenance scheduling. Regular checks ensure accuracy and prevent unexpected failures. Adjust calibration intervals based on operational demands and manufacturer recommendations. Staying consistent with calibration helps maintain efficiency, reduces downtime, and extends the motor’s lifespan.

What Safety Precautions Are Necessary During Motor Calibration Procedures?

Imagine you’re steering a stormy sea; safety gear is your sturdy ship, keeping you protected. During motor calibration, always wear safety gear like gloves and goggles to guard against sparks or debris. Keep emergency shutdowns accessible; they are your lighthouse guiding you to safety. Make certain the workspace is clear, and follow all safety protocols meticulously. This vigilance prevents accidents, making certain your calibration process stays smooth and safe.

Can Calibration Adjustments Improve Motor Lifespan and Reliability?

Yes, calibration adjustments can improve your motor’s lifespan and reliability. By regularly calibrating and adjusting for motor wear, you prevent overloading and inefficient operation. Maintaining the right calibration frequency guarantees your motor runs smoothly, reducing stress on components and minimizing downtime. Proper calibration helps catch early signs of wear, allowing you to make necessary adjustments and extend the motor’s overall durability and dependable performance over time.

Are There Industry Standards or Certifications for Motor Calibration Accuracy?

Imagine you’re ensuring your motor meets industry standards. Yes, there are certifications like ISO 17025 that validate calibration accuracy, ensuring regulatory compliance. For example, a manufacturing plant achieved better consistency and safety after obtaining calibration certifications for their motors. These standards set benchmarks for precision, helping you maintain quality and reliability. Certifying your calibration processes demonstrates your commitment to excellence and adherence to industry regulations.

What Are Common Signs Indicating a Need for Recalibration?

If you notice sensor drift or inconsistent readings from your motor, it’s a clear sign you need recalibration. These issues indicate the sensor’s accuracy has diminished, potentially affecting performance. Regularly monitor your motor’s output, and if you see fluctuations or irregularities, don’t delay recalibration. Addressing these signs promptly ensures your motor operates efficiently and maintains the precision required for ideal functioning.

Conclusion

Mastering motor calibration is vital for peak performance. Did you know that proper calibration can improve motor efficiency by up to 15%? By understanding load torque, voltage parameters, and analyzing data carefully, you guarantee your motor runs smoothly and reliably. Keep detailed records to track progress and adjustments. Remember, skipping these steps risks costly downtime. Stay precise, stay informed, and your motor will perform at its best every time.