Motor calibration involves adjusting key parameters like voltage, current, and feedback signals to guarantee your motor runs smoothly and accurately. It includes understanding different motor types, such as brushless and stepper motors, as well as using sensors and encoders for precise feedback. Proper calibration also involves troubleshooting, using the right tools, and following best practices for consistent performance. Stay with us to uncover detailed tips and techniques to perfect your motor calibration skills.

Key Takeaways

- Understand different motor types (brushless, stepper) and their specific calibration needs for optimal performance.

- Learn essential calibration parameters such as voltage, current, encoder resolution, and feedback signals.

- Familiarize with tools like multimeters, oscilloscopes, and torque meters used for precise calibration measurements.

- Follow best practices like regular calibration schedules, proper sensor alignment, and detailed record-keeping.

- Recognize troubleshooting steps including sensor checks, software reviews, and recalibration to maintain motor accuracy.

Understanding Motor Types and Their Functions

Understanding motor types and their functions is essential for selecting the right motor for your application. Two common types are brushless motors and stepper motors. Brushless motors, also known as BLDC motors, deliver high efficiency, quiet operation, and precise control, making them ideal for drones, electric vehicles, and robotics. They have no brushes, which reduces wear and maintenance. Stepper motors, on the other hand, move in discrete steps, allowing precise positioning without feedback systems. You’ll find them in 3D printers, CNC machines, and automation systems. Each motor type offers unique advantages—brushless motors excel in continuous, high-speed applications, while stepper motors are perfect for accurate, incremental movements. Understanding these differences helps you choose the best motor for your specific needs. Additionally, natural materials used in Waldorf toys promote tactile familiarity and sensory development, which can be beneficial when selecting motor-based educational toys that emphasize physical interaction and fine motor skills.

Key Electrical Components in Motor Calibration

To calibrate a motor effectively, you need to understand the key electrical components involved. Devices like voltage regulation units, current measurement tools, and power supply units play vital roles in ensuring accurate calibration. Mastering these components helps you maintain ideal motor performance and reliability. Additionally, understanding how to optimize electrical signal quality can significantly improve calibration precision and motor responsiveness.

Voltage Regulation Devices

Voltage regulation devices are essential components in motor calibration because they guarantee the motor receives a stable and consistent voltage supply. They play a key role in power stabilization by adjusting fluctuations in voltage, preventing surges or drops that could affect motor performance. These devices ensure that the motor operates efficiently and accurately during calibration, reducing the risk of errors caused by inconsistent power. By maintaining a steady voltage level, voltage regulation devices safeguard your equipment from potential damage and improve overall reliability. They are especially important in environments with fluctuating power supplies or sensitive calibration processes. Using these devices helps you achieve precise calibration results and extends the lifespan of your motor and related components. Incorporating HEPA filtration in the environment can further improve calibration accuracy by reducing airborne contaminants that may interfere with sensitive measurements.

Current Measurement Tools

Current measurement tools are essential for accurate motor calibration because they provide precise readings of the electrical current flowing through the motor. These tools help you monitor how the motor responds under different conditions, such as when a dynamic load is applied, which can cause fluctuations in current. Using clamp meters or shunt resistors allows you to measure current without interrupting operation. Temperature sensors are often integrated with current measurement tools to track how heat affects current flow, especially during prolonged operation. This data helps prevent overheating and guarantees ideal performance. Accurate current measurement enables you to identify issues early, optimize calibration settings, and maintain motor efficiency and longevity. Mastering these tools is key to achieving precise, reliable motor calibration. Understanding electrical components is fundamental to interpreting measurement data effectively.

Power Supply Units

Power supply units (PSUs) are critical components in motor calibration setups because they provide the necessary electrical energy to operate the motor accurately. They guarantee stable power delivery, which is essential for precise calibration. Many PSUs include battery backups, allowing your system to maintain power during outages, preventing calibration errors. Proper power distribution from the PSU ensures consistent voltage and current, reducing fluctuations that could compromise your motor’s performance. When selecting a PSU, consider its capacity to handle your motor’s power demands, as well as its ability to integrate smoothly with your calibration system. Reliable power sources minimize downtime and improve calibration accuracy, making PSUs a crucial part of any motor calibration process. Incorporating well-being tips such as ensuring stable power sources can also contribute to the overall success of your calibration activities.

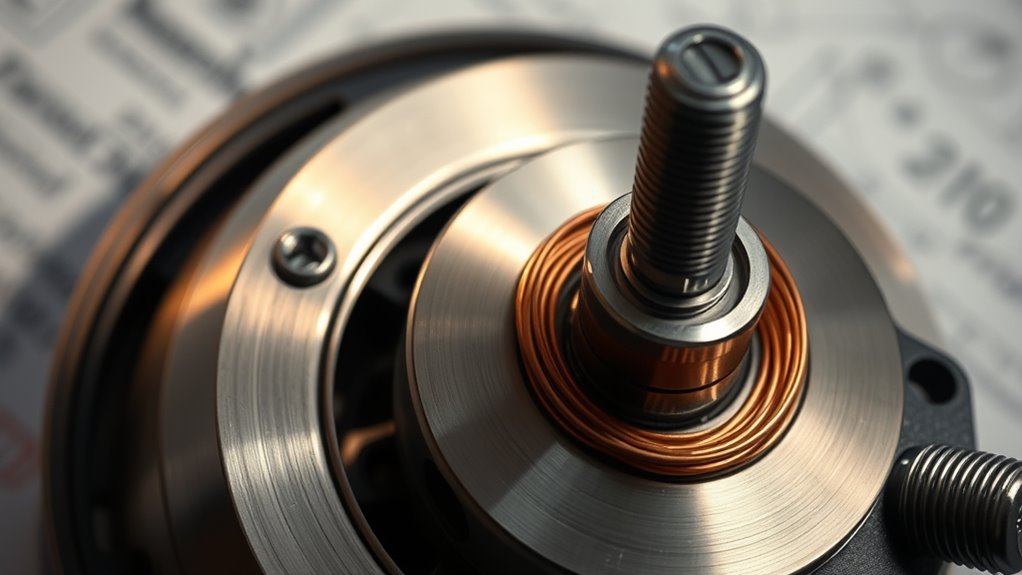

The Role of Sensors and Encoders

Sensors and encoders are essential components in motor calibration because they provide real-time feedback on the motor’s position, speed, and other critical parameters. This feedback helps you fine-tune the motor for precision and reliability. Sensor accuracy determines how precisely the system detects the motor’s movements, directly impacting calibration quality. Encoders, on the other hand, convert rotational motion into electrical signals; their encoder resolution indicates how many discrete steps they can detect per revolution. Higher resolution means more detailed data, leading to better control and smoother operation. By monitoring these parameters, you can identify discrepancies and adjust settings accordingly, ensuring ideal performance. Indoor air quality can be up to 5 times worse than outdoor air, highlighting the importance of accurate sensors and encoders in maintaining optimal conditions. Without accurate sensors and high-resolution encoders, calibration becomes guesswork, risking errors and inefficiencies in your motor’s operation.

Common Calibration Techniques and Methods

To achieve accurate motor calibration, you can employ several common techniques that help fine-tune performance and guarantee reliability. These include methods like manual adjustments, iterative testing, and leveraging advanced calibration algorithms. Automation plays a key role, enabling calibration process automation for consistency and efficiency. Techniques such as real-time feedback and adaptive algorithms allow you to refine motor behavior precisely. Here’s a quick overview:

| Technique | Description | Benefits |

|---|---|---|

| Manual Calibration | Adjusting settings based on observations | Simple, cost-effective |

| Iterative Testing | Repeated tests to improve accuracy | Improved precision |

| Advanced Algorithms | Using complex algorithms for calibration | Faster, more accurate results |

| Calibration Process Automation | Automating steps for efficiency | Saves time, reduces errors |

| Sensor Feedback Optimization | Using sensor data to refine calibration | Enhances reliability |

These methods streamline the calibration process, ensuring your motor performs most effectively. Additionally, incorporating remote hackathons can facilitate collaboration among teams working on calibration algorithms, leading to innovative solutions and improved methodologies.

Essential Calibration Parameters and Settings

Understanding the essential calibration parameters and settings is crucial for optimizing your motor’s performance. Key factors include torque optimization, which ensures your motor delivers the right power without overexertion, and temperature compensation, which adjusts settings to prevent performance drops caused by heat fluctuations. Proper calibration involves setting parameters like current limits and speed thresholds to match your specific application. Temperature sensors help your motor adapt to changing conditions, maintaining efficiency and preventing overheating. Being aware of narcissistic behaviors can help in managing interactions with difficult personalities, similar to how proper calibration manages motor performance. By fine-tuning these parameters, you ensure smoother operation, improved lifespan, and energy efficiency. Keep in mind that accurate calibration of these settings forms the foundation for reliable, high-performance motor operation, helping you avoid issues and achieve consistent results.

Troubleshooting Calibration Issues

When calibration issues arise, they can cause your motor to perform unpredictably or inefficiently. To troubleshoot effectively, start by checking sensor alignment; misaligned sensors often lead to inaccurate readings and calibration errors. Confirm all sensors are properly positioned and secured. If problems persist, turn to software troubleshooting. Review calibration logs for errors or inconsistencies, and verify that your calibration software is up to date. Sometimes, recalibrating from scratch or resetting calibration settings can resolve issues. Also, look for any software conflicts or communication errors between hardware and calibration tools. By systematically inspecting sensor alignment and performing software troubleshooting, you can identify and resolve calibration problems quickly, restoring your motor’s peak performance. Additionally, consulting calibration procedures can provide detailed guidance to ensure all steps are correctly followed.

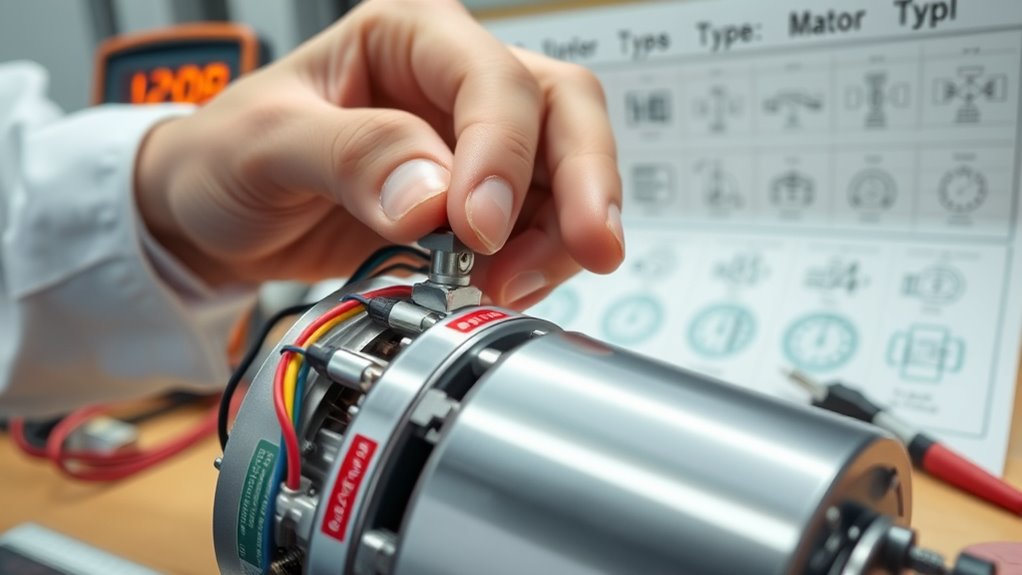

Tools and Equipment for Motor Calibration

Having the right tools and equipment is essential for accurate motor calibration. You’ll need precise measurement devices like torque meters, multimeters, and oscilloscopes to ensure correct readings. A clean, stable workspace helps prevent errors during calibration. Motor lubricant is crucial for maintaining smooth operation and preventing wear, which can affect calibration accuracy. Using quality calibration certificates ensures your equipment’s precision and adherence to standards. You should also have calibration tools such as reference standards, test benches, and software for data analysis. Proper calibration equipment minimizes errors and increases reliability. Always verify your tools’ accuracy regularly, and keep detailed records of calibration procedures and results. With the right tools, you’ll ensure your motor operates at its best and meets performance specifications. Additionally, understanding interior design principles can contribute to creating well-organized and efficient workspaces that facilitate precise calibration tasks.

Best Practices for Accurate Calibration

To achieve accurate motor calibration, you need to follow consistent procedures and pay close attention to detail. Regularly check your motor alignment to prevent errors and ensure smooth operation. Establish and adhere to calibration schedules to maintain accuracy over time. Proper timing helps catch drift or misalignments early, saving you time and effort later. Use a visual aid like this table to plan your calibration routine:

| Step | Action | Frequency |

|---|---|---|

| Check alignment | Adjust motor components if needed | Monthly |

| Perform calibration | Use proper tools and methods | Quarterly |

| Record results | Track changes for future reference | After each calibration |

| Inspect connections | Ensure secure wiring | Bi-weekly |

| Review schedules | Update based on performance feedback | Annually |

Following these practices guarantees your motor remains precisely calibrated and aligned.

Integrating Calibration Data Into System Performance

Integrating calibration data into system performance is essential for maintaining ideal operation and detecting issues early. Motor data integration allows you to feed accurate calibration results directly into your control systems, ensuring consistent performance. By doing this, you enable real-time adjustments that improve system reliability and efficiency. When calibration data is seamlessly incorporated, it supports system performance optimization, helping you fine-tune motor behavior for different conditions. This process also simplifies troubleshooting, as you can quickly identify deviations from expected performance. Ultimately, integrating calibration data ensures your system runs smoothly, reducing downtime and extending equipment lifespan. Focus on establishing reliable data transfer methods and regular updates to keep your system calibrated and performing at its best.

Frequently Asked Questions

How Often Should Motor Calibration Be Performed for Optimal Performance?

You should perform motor calibration regularly, ideally following a set calibration schedule to prevent motor drift. Usually, calibrate every few months or after any significant changes to your equipment or environment. Regular calibration helps maintain peak performance, reduces errors, and extends your motor’s lifespan. Keep track of your calibration dates so you can catch drift early and guarantee your motor operates smoothly and accurately over time.

What Safety Precautions Are Necessary During Motor Calibration?

Think of calibration hazards as lurking shadows—you need safety gear to light your path. Always wear protective goggles, gloves, and ear protection to shield against unexpected sparks or debris. Make sure the motor is powered down before adjustments, and keep the workspace clear of clutter. By taking these safety precautions, you turn potential dangers into mere ripples, letting you focus on perfecting your calibration without risking injury.

Can Calibration Procedures Be Automated for Industrial Motors?

Yes, calibration procedures can be automated for industrial motors. You’ll need calibration software that streamlines the process, ensuring consistency and accuracy. However, be aware of automation challenges like integration with existing systems and maintaining precision. Regularly update your calibration software and monitor automated processes to prevent errors. With proper setup, automation saves time, reduces manual effort, and improves overall motor performance.

How Do Environmental Factors Affect Motor Calibration Accuracy?

Environmental factors like ambient temperature and humidity levels can profoundly impact your motor calibration accuracy. Fluctuations in temperature cause material expansion or contraction, affecting measurements, while high humidity can lead to corrosion or electrical issues. To guarantee precise calibration, you should control the environment or perform calibrations in controlled settings. Monitoring these factors helps maintain consistent motor performance and reduces calibration errors caused by external environmental influences.

What Are Signs Indicating a Need for Recalibration?

You’ll notice a need for recalibration if sensor drift causes inconsistent readings or if mechanical wear leads to decreased motor performance. Signs include irregular motor responses, unexpected vibrations, or a drop in accuracy. Environmental factors may also cause these issues over time. Regularly checking for these signs helps guarantee your motor stays properly calibrated, preventing errors and maintaining ideal operation. Don’t ignore these cues—recalibrate promptly to keep everything running smoothly.

Conclusion

Mastering motor calibration might seem intimidating, but with the right knowledge, you hold the key to ideal system performance. Think of calibration as the heartbeat of your motor—keep it steady, precise, and aligned. Remember, every tweak and adjustment is a step toward perfection. So don’t just aim for good enough—strive for excellence. After all, isn’t it your dedication that transforms ordinary motors into extraordinary machines?