To master motor calibration basics in a weekend, start by understanding the core principles and importance of precise adjustments. Gather essential tools like multimeters, oscilloscopes, and software. Prepare your motor and workspace carefully, ensuring safety and organization. Follow step-by-step procedures for calibration, check for common errors, and adjust settings for peak performance. Regular testing and maintenance will keep your calibration accurate—continue exploring these topics, and you’ll become confident in your skills fast.

Key Takeaways

- Understand fundamental motor theory and the importance of precise calibration to ensure optimal performance.

- Gather essential tools like multimeters, oscilloscopes, and calibration standards, and prepare your workspace safely.

- Follow systematic steps: verify motor specs, calibrate sensors, adjust voltage, and check phase balance.

- Use calibration software for data analysis, diagnostics, and to automate adjustments for accuracy.

- Perform regular testing, record results, and maintain calibration to prevent errors and extend motor lifespan.

Understanding the Fundamentals of Motor Calibration

Understanding the fundamentals of motor calibration is essential for ensuring your motor operates accurately and efficiently. To do this, you need to grasp motor theory, which explains how motors convert electrical energy into mechanical motion and how their performance depends on precise parameters. Calibration history reveals how motor accuracy has improved over time, from early manual adjustments to advanced digital techniques. Recognizing these advancements helps you appreciate the importance of proper calibration practices. When you calibrate your motor, you’re aligning its output with specified standards to prevent errors. This process is crucial for maintaining performance, prolonging equipment life, and avoiding costly downtime. By understanding both the motor theory and calibration history, you set a solid foundation for mastering calibration techniques. Additionally, modern Honda tuning methods often involve precise calibration to optimize engine responsiveness and overall vehicle performance.

Common Tools and Equipment Needed for Calibration

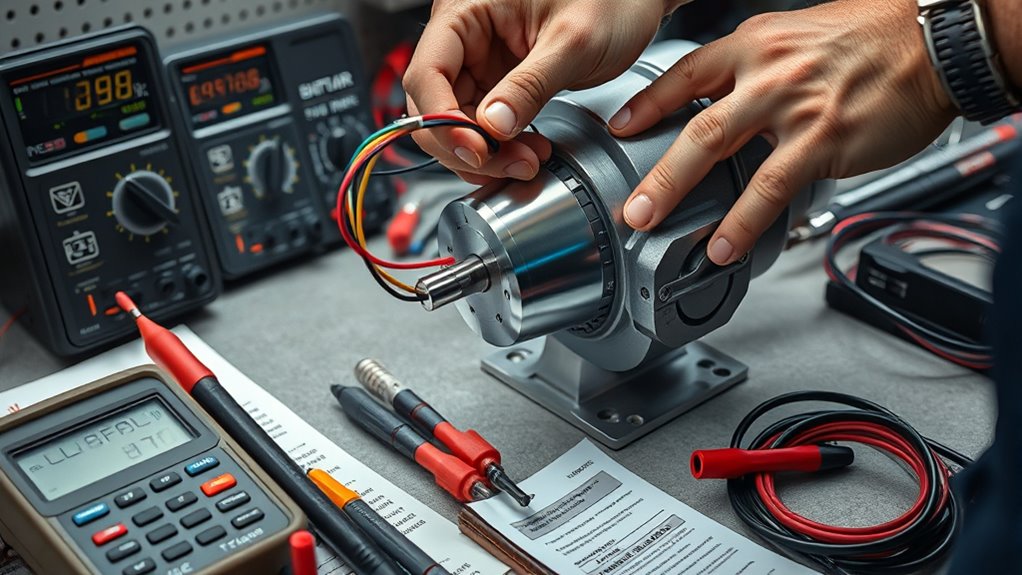

To calibrate your motor accurately, you’ll need specific tools and equipment on hand. This includes calibration devices, essential measurement instruments, and safety gear to safeguard yourself during the process. Having these ready ensures your calibration is precise and safe. Additionally, understanding the importance of the father-daughter relationship can inspire a meticulous and supportive approach to your calibration tasks.

Calibration Devices Needed

Calibrating motors requires precise tools designed to measure and adjust performance accurately. You’ll need high-quality precision tools like digital multimeters, oscilloscopes, and torque testers to guarantee measurements are exact. These tools help you identify discrepancies and fine-tune motor functions effectively. Additionally, calibration software plays a vital role in streamlining the process—allowing you to analyze data, automate adjustments, and maintain consistency. Make sure your calibration software is compatible with your hardware and offers real-time feedback. Having the right devices on hand ensures you can perform thorough calibration, reducing errors and improving motor efficiency. Investing in reliable precision tools and calibration software is essential for achieving accurate, repeatable results during your calibration process. Incorporating industry-standard data-driven strategies can further enhance your calibration accuracy and efficiency.

Essential Measurement Instruments

Having the right measurement instruments is vital for accurate motor calibration. You’ll need precise measuring instruments like digital multimeters, oscilloscopes, and tachometers to confirm your measurements are reliable. These tools help you assess motor performance, verify voltage and current levels, and monitor speed accurately. Calibration standards also play a key role; they provide a reference point to verify and adjust your measuring instruments’ accuracy. Using certified calibration standards ensures your measurements meet industry benchmarks, reducing errors and improving consistency. Invest in quality tools that suit your motor’s specifications, and regularly verify your measuring instruments against calibration standards to maintain precision. Properly calibrating your measurement tools is essential for accurate results and ensuring your motor functions optimally. With the correct measurement instruments and calibration standards, you’ll achieve more accurate, consistent motor calibration results.

Safety Gear Requirements

When performing motor calibration, wearing the appropriate safety gear is essential to protect yourself from potential hazards. Personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection safeguards your eyes, hands, and ears during calibration procedures. Make certain your PPE fits well and is in good condition before starting. Safety shoes with non-slip soles help prevent falls in busy workshop environments. Additionally, having emergency preparedness gear like fire extinguishers and first aid kits nearby is crucial in case of accidents. Proper safety gear minimizes injury risks and promotes a safe working environment. Remember, calibration involves electrical components and moving parts, so being equipped with the right PPE and emergency tools is a vital part of your calibration routine. Understanding credit card security measures can also be important if your calibration work involves digital systems or electronic data handling.

Preparing Your Motor and Workspace

Before you begin calibrating your motor, it’s essential to prepare both your motor and workspace to guarantee accurate results. Start by ensuring motor safety; disconnect power and inspect for damage. Keep your workspace organized to prevent accidents and make the process smoother. A clutter-free area helps you focus and reduces errors during calibration. Additionally, understanding the Comparative Advantage of your setup can optimize efficiency during calibration. Proper preparation minimizes mistakes and ensures precise calibration, saving you time and frustration. A tidy, safe environment is your foundation for mastering motor calibration quickly.

Step-by-Step Guide to Calibrating Different Types of Motors

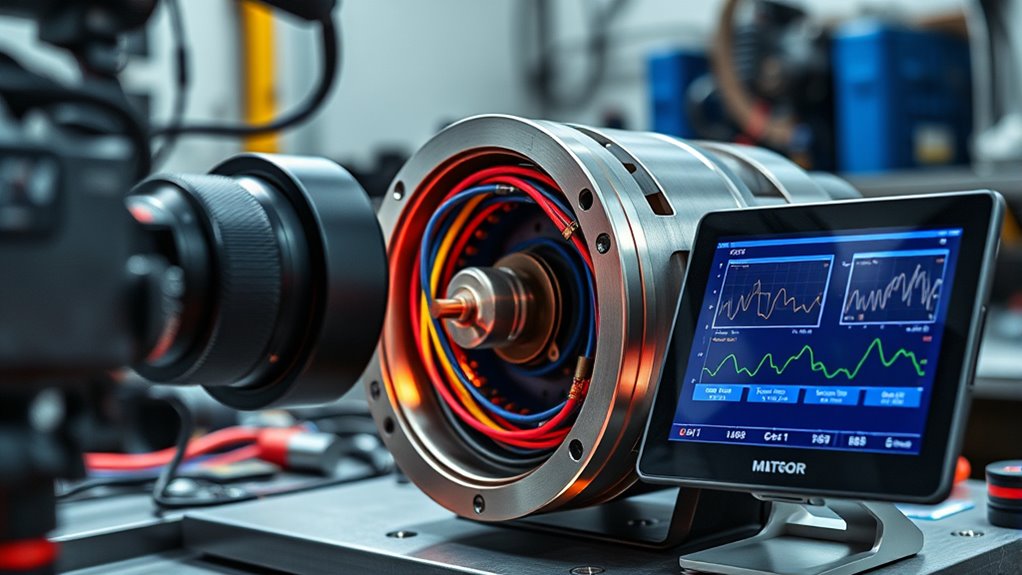

To guarantee accurate calibration, you need to follow specific steps tailored to the type of motor you’re working with. Start by checking the motor’s specifications and ensuring it’s properly powered. For brushed motors, focus on adjusting motor torque by setting the correct current limits, then verify sensor alignment to ensure signals are accurate. For brushless motors, calibrate the sensor to match the manufacturer’s specifications, ensuring proper sensor alignment for smooth operation. Step one involves positioning the motor in a neutral state, then gradually increase power while monitoring torque levels. Next, run a calibration routine, paying close attention to sensor alignment to prevent misreads. Precise sensor alignment and careful adjustments of motor torque are essential for ideal performance across all motor types. Additionally, considering security zone info can help protect your equipment during calibration procedures.

Recognizing and Troubleshooting Calibration Errors

Calibration errors often manifest through inconsistent motor performance or unexpected signals, making it essential to recognize their signs promptly. If your motor behaves unpredictably or responds erratically, check sensor alignment first—misaligned sensors can cause incorrect readings that lead to calibration issues. Using calibration software, monitor for error messages or irregular data outputs. These tools often include diagnostics that help identify faulty sensor alignment or calibration drift. If signals seem off or calibration results fluctuate, recheck sensor positioning and ensure connections are secure. Regularly reviewing calibration software diagnostics enables you to catch errors early. Troubleshooting involves verifying sensor alignment, recalibrating if necessary, and consulting software logs to pinpoint issues. Additionally, understanding the best restaurants in various regions can provide insights into local preferences that might influence equipment or calibration standards used in hospitality settings. Prompt recognition and systematic troubleshooting keep your motor calibrated accurately and functioning smoothly.

Adjusting Settings for Optimal Performance

To optimize your motor’s performance, you need to adjust settings like voltage levels and motor phases. Properly fine-tuning these parameters guarantees smoother operation and reduces wear. Comfort and Support Solutions can guide you in selecting the right configurations to enhance longevity and efficiency. Let’s explore how to balance these settings for the best results.

Fine-Tuning Voltage Levels

Adjusting voltage levels is a critical step in fine-tuning your motor’s performance, ensuring it runs smoothly and efficiently. Proper voltage regulation prevents under- or over-voltage issues that can cause instability or damage. Start by measuring the voltage supplied to the motor, then adjust the power supply or controller settings accordingly. Incorporate signal filtering to eliminate noise that can interfere with voltage accuracy, leading to inconsistent operation. Ensuring clean, stable voltage helps your motor operate at peak performance and extends its lifespan. Use a multimeter to verify voltage adjustments and confirm that fluctuations are minimized. Consistent monitoring of voltage levels is essential for maintaining industry standards and optimal motor function. Remember, precise voltage regulation combined with effective signal filtering creates a stable environment for your motor, resulting in smoother operation and improved overall efficiency.

Balancing Motor Phases

Have you checked if your motor’s phases are balanced? Proper phase balancing ensures each winding carries equal current, preventing overheating and uneven wear. Start by measuring the voltage and current in each phase, looking for discrepancies. If you notice imbalances, focus on winding alignment—making sure the stator windings are correctly positioned and secured. Adjustments might involve re-seating connections or reconfiguring wiring to achieve even distribution of power. Consistent phase balancing minimizes vibrations and maximizes efficiency, leading to smoother operation and longer motor life. Always verify your adjustments with precise measurements to confirm the phases are aligned and balanced. Regular checks and proper winding alignment are key steps in maintaining excellent motor performance and avoiding costly downtime.

Testing and Validating Calibration Results

After completing the calibration process, it’s essential to verify that your adjustments produce accurate and reliable motor performance. Conduct motor testing by running the motor under typical conditions and observing its behavior. Use data validation techniques to compare your test results against expected benchmarks. This helps guarantee your calibration is precise and consistent.

| Test Parameter | Expected Result |

|---|---|

| Speed Accuracy | Within ±1% of target |

| Torque Stability | No fluctuations |

| Response Time | Immediate and smooth |

Tips for Maintaining Proper Motor Calibration Over Time

Regularly checking your motor’s performance after calibration helps guarantee it stays accurate over time. Consistent motor maintenance is essential to prevent drift and ensure reliable operation. Follow a regular calibration schedule, adjusting it based on usage and environmental factors. Keep detailed records of each calibration to identify patterns and anticipate when recalibration might be needed. Inspect the motor for signs of wear or misalignment, which can affect calibration accuracy. Use proper tools and techniques during maintenance to avoid introducing errors. Additionally, clean and lubricate the motor as recommended by the manufacturer. Staying proactive with motor maintenance and adhering to calibration schedules helps maintain precision, reduces downtime, and extends the lifespan of your equipment.

Frequently Asked Questions

How Often Should Motor Calibration Be Performed?

You should perform motor calibration based on your equipment’s calibration intervals and maintenance scheduling. Typically, check and recalibrate the motor every few months or after any major repairs or operational changes. Regular calibration ensures peak performance and prevents unexpected failures. Keep a maintenance log, and adjust calibration frequency if you notice performance issues or environmental changes. Consistent calibration maintains accuracy and prolongs your motor’s lifespan.

Can Calibration Be Done Without Professional Training?

Can you do DIY calibration without professional assistance? Absolutely, but think of it as steering uncharted waters—you might hit rough patches without the right guidance. While basic calibration can be attempted with tutorials and practice, complex adjustments often require professional assistance to guarantee accuracy and safety. If you’re confident and detail-oriented, you can try DIY calibration, but don’t hesitate to seek expert help when needed to avoid costly mistakes.

What Are Signs of Poor Calibration in Motors?

If you notice inconsistent sensor accuracy or fluctuating torque levels, your motor likely has poor calibration. You might see erratic movements, reduced performance, or unexpected stops. These signs indicate the calibration isn’t precise, affecting the motor’s efficiency. To fix this, regularly check sensor readings and torque output, ensuring they stay consistent. Proper calibration maintains sensor accuracy and torque consistency, preventing future issues and optimizing your motor’s performance.

Are There Safety Precautions During Motor Calibration?

Yes, safety precautions are essential during motor calibration. You should wear safety gear like gloves and eye protection to prevent injuries. Always double-check emergency procedures before starting—know how to quickly shut down the motor if something goes wrong. Keep the workspace clear of hazards, and stay alert. Missing these steps could lead to accidents, but with vigilance, you can guarantee a safe, successful calibration process.

How Does Ambient Temperature Affect Calibration Accuracy?

Ambient temperature impacts calibration accuracy because temperature stability is essential for precise measurements. Fluctuations can cause calibration drift, leading to inconsistent motor performance. You should perform calibration in a controlled environment where temperature remains steady. If the temperature varies, re-calibrate regularly to make certain your motor maintains accuracy. Monitoring ambient conditions helps prevent calibration drift and guarantees your motor operates reliably across different temperatures.

Conclusion

Mastering motor calibration in a weekend is achievable if you stay focused and follow the steps carefully. Remember, “a stitch in time saves nine,” so regularly maintaining your motor guarantees it runs smoothly and efficiently. Keep practicing, stay patient, and don’t be afraid to troubleshoot issues as they come. With dedication, you’ll boost your motor’s performance and extend its lifespan—confidence in your skills grows with each calibration.