When comparing L Track and S Track for safety, it’s important to understand their design differences, load capacities, and material quality. L Tracks are durable, offering a sleek look, while S Tracks are versatile and easier to install on uneven surfaces. Proper installation and regular maintenance are what truly keep cargo secure—not just the system type. Knowing what matters most guarantees your setup stays safe, so keep exploring to get all the facts.

Key Takeaways

- Proper installation and maintenance are crucial for both L and S tracks to ensure cargo security and safety.

- Myths about system strength overlook the importance of material quality and correct usage.

- Load capacity and even weight distribution directly impact track durability and safety performance.

- Aesthetic preferences should not compromise safety; choose systems based on application needs and proper installation.

- High-quality, corrosion-resistant materials extend track lifespan and reduce safety risks over time.

Understanding the Design Differences Between L Track and S Track

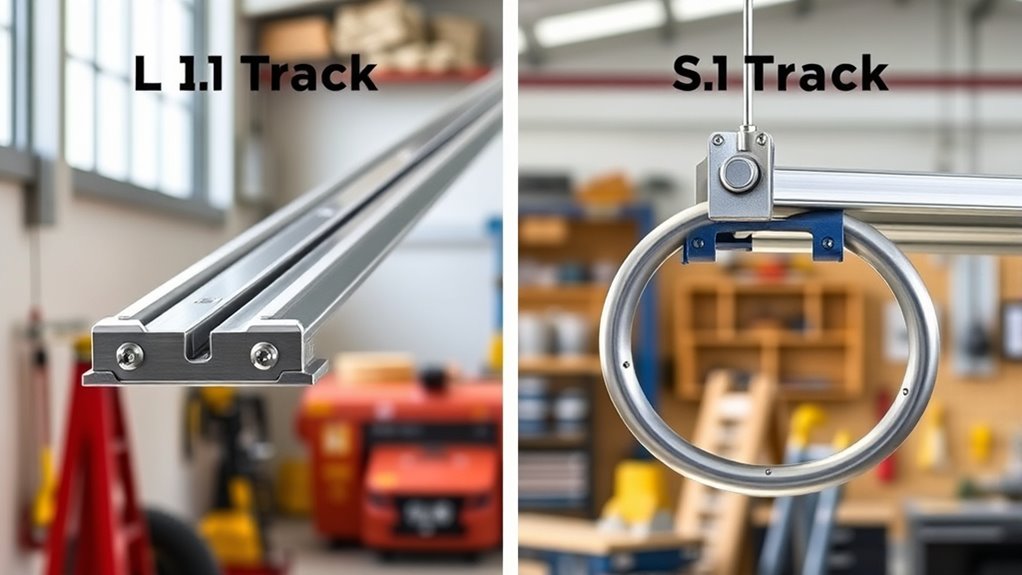

While both L Track and S Track are designed to secure cargo effectively, their structural differences considerably impact safety and compatibility. L Track typically uses a flat, sturdy metal profile made from aluminum or steel, emphasizing durability and strength. Its installation techniques involve mounting directly to the vehicle’s surface using screws or bolts, ensuring a secure fit. In contrast, S Track features a slightly curved profile, often made from similar track materials but with a design optimized for quick attachment and release. The installation of S Track may include brackets or special anchors for added stability. These material choices and installation methods influence how well each track system withstands load and vibration, directly affecting safety and overall cargo security. Additionally, understanding the load-bearing capacity of each track type helps ensure proper safety standards are maintained during use.

Common Safety Misconceptions Surrounding Track Systems

Many people assume that L Track and S Track systems are equally safe simply because they both secure cargo effectively. However, safety isn’t solely about securing loads; it also involves proper installation and understanding each system’s limitations. A common misconception is that track customization doesn’t impact safety, but poorly chosen or installed tracks can compromise security. Additionally, some believe that aesthetic considerations are secondary, but choosing tracks that blend seamlessly with your vehicle can prevent accidental damage or misalignment. Safety isn’t just about the track’s strength; it’s about selecting the right system for your specific needs and ensuring it’s properly installed. Paying attention to these factors helps you avoid dangerous mistakes and ensures your cargo stays secure on every trip. Proper risk assessment of your cargo and vehicle setup can further enhance safety.

How Load Capacity Influences Track Safety and Performance

Your track’s load capacity directly affects its safety and durability. When you overload or distribute weight improperly, it can shorten the track’s lifespan and compromise stability. Understanding these factors helps you maintain ideal performance and prevent costly damage. Proper load distribution is essential in ensuring the longevity and safety of your track system.

Load Limits and Durability

Load limits directly impact track safety and performance by determining how much weight the tracks can support without compromising their integrity. Exceeding these limits can lead to deformation or failure. To guarantee durability, consider:

- The maximum load weight your track system can handle.

- Proper material selection that offers strength and resilience.

- Regular inspections to identify stress signs early.

- Appropriate support structures to distribute weight evenly.

Ensuring your track system is compliant with safety standards helps prevent accidents and extends its lifespan. Choosing the right materials, such as high-strength steel or reinforced aluminum, helps maintain durability under heavy loads. Understanding load limits allows you to optimize performance and prevent costly repairs. When you respect these limits, your tracks perform reliably, safely supporting both daily operations and unexpected stresses.

Impact on Track Longevity

Understanding how load capacity affects track longevity is essential for maintaining safe and efficient operations. When your tracks are properly rated for the loads they carry, they tend to last longer, reducing the need for frequent repairs or replacements. Overloading can cause track deformation, which not only shortens lifespan but also impacts track aesthetics, making them look worn and unsafe. Additionally, higher load capacities often mean higher installation costs, but investing in the right track type guarantees durability and safety over time. Proper load management preserves the structural integrity of your tracks, keeping them functional and visually appealing. Regular inspections and maintenance practices play a vital role in extending track life and ensuring safety. Ultimately, paying attention to load capacity helps you avoid unnecessary expenses and ensures your track system remains reliable for the long haul.

Proper Weight Distribution

Proper weight distribution is essential for maintaining track safety and ideal performance. When loads are uneven, it can cause track misalignment, reducing longevity and risking accidents. To guarantee maximum load capacity, consider these factors:

- Distribute weight evenly across all track sections.

- Avoid overloading any single point, which can compromise track aesthetics.

- Regularly check for signs of uneven wear or sagging.

- Choose track color options that clearly indicate weight limits.

- Ensuring consistent load distribution helps prevent structural damage and enhances overall durability.

Maintaining proper weight distribution not only supports safety but also preserves the track’s appearance, ensuring it looks neat and functional. Whether you prefer sleek black or vibrant color options, balanced loads help keep your track aesthetically pleasing and structurally sound, boosting performance and safety.

The Role of Material Quality in Track Durability and Safety

The quality of materials used in track construction directly impacts its durability and safety. Stronger, longer-lasting materials reduce the risk of failures, especially under heavy loads. Additionally, corrosion resistance guarantees the track remains reliable over time, even in harsh environments. For example, selecting materials with superior strength-to-weight ratios can further enhance track resilience and safety.

Material Strength and Longevity

Material quality plays a pivotal role in determining the durability and safety of train tracks, as stronger, high-quality materials can better withstand the stresses of daily operation. When selecting track materials, consider:

- Durability over time, reducing the need for frequent repairs.

- Resistance to wear and fatigue, ensuring smooth operation.

- Impact on track aesthetics, maintaining a clean, professional appearance.

- Influence on installation cost, where higher-quality materials may initially cost more but save money long-term.

Choosing superior materials enhances longevity, safety, and performance, even under heavy use. Poor-quality materials may lower upfront costs but can lead to frequent replacements, safety risks, and compromised track aesthetics. Ultimately, investing in robust materials ensures safer, more reliable rail infrastructure.

Corrosion Resistance Factors

Corrosion resistance is a critical factor that directly impacts the longevity and safety of train tracks. When choosing materials, prioritize those with high corrosion resistance to prevent rust and degradation over time. Poor corrosion resistance can weaken the track structure, increasing the risk of failure and accidents. Material durability is essential for maintaining track integrity under harsh weather conditions, such as rain, snow, and humidity. High-quality materials, like galvanized steel or coated alloys, resist corrosion better than basic steel, ensuring longer-lasting performance. Investing in tracks with superior corrosion resistance reduces maintenance costs and downtime. Additionally, selecting materials with proven dog name durability can further enhance the overall safety and lifespan of the track system. Ultimately, understanding how material quality influences corrosion resistance helps you select safer, more durable tracks that stand the test of time.

Proper Installation Techniques and Their Impact on Security

Proper installation techniques are crucial because they directly influence the security and longevity of both L track and S track systems. You need to confirm track compatibility and maintain installation precision to prevent issues later on. Here are four key steps to maximize security:

Proper installation ensures the security and durability of L and S track systems for long-term safety.

- Verify compatibility with your vehicle or setup before installation.

- Use precise measurements to ensure correct alignment.

- Secure tracks firmly to avoid movement or loosening.

- Follow manufacturer instructions meticulously for proper fastening.

- Pay attention to track design features that facilitate secure attachment and long-term stability.

Neglecting these steps can lead to compromised security, system failure, or damage over time. When you prioritize accurate installation techniques, you improve overall safety and ensure your tracks perform reliably. Remember, proper installation isn’t just about fitting parts—it’s about safeguarding your setup for the long haul.

Maintenance and Inspection: Ensuring Long-Term Safety

Maintaining your L track or S track system is essential for long-term safety and reliable performance. Regular inspections help identify wear, damage, or loose components before they become serious issues. Incorporate proper lubrication practices to reduce friction and prevent parts from seizing or wearing prematurely. Be sure to follow manufacturer recommendations for lubricant types and application frequency. Cleaning routines are equally important; remove dirt, debris, and grime that can accumulate and hinder smooth operation. Use appropriate cleaning tools and avoid harsh chemicals that could damage the tracks. Additionally, understanding the effects of proper maintenance can help you optimize your system’s longevity and safety. Consistent maintenance guarantees your system functions safely over time, minimizes unexpected failures, and extends its lifespan. Staying vigilant with inspections, lubrication, and cleaning keeps your setup safe and dependable for years to come.

Real-World Performance: Case Studies and User Experiences

Real-world experiences reveal how L track and S track systems perform under various conditions, providing valuable insights beyond theoretical comparisons. Users report that:

Real-world use shows L and S tracks perform differently depending on conditions and priorities.

- Track customization options allow for tailored setups, enhancing functionality and style.

- L tracks often excel in aesthetic considerations, blending seamlessly into modern designs.

- S tracks tend to be more versatile when dealing with uneven surfaces or heavy loads.

- User feedback highlights that installation ease varies; some find L tracks more straightforward for specific applications.

These case studies show that your choice depends on your priorities—whether aesthetic appeal or practical performance. While both systems can be safe when properly installed and maintained, real-world use highlights differences that aren’t always clear in technical specs. Your needs ultimately determine the best fit.

Making an Informed Choice Based on Your Specific Needs

Choosing between L track and S track systems ultimately depends on your specific needs and priorities. If you value sleek track aesthetics that blend seamlessly with your decor, L tracks often offer a more modern, minimalist look. On the other hand, S tracks can be more versatile and easier to customize for different applications. Installation costs also play a significant role; L tracks typically require a more precise setup, which might increase installation expenses. Consider your budget and how much you’re willing to invest upfront. Think about how the track style aligns with your space’s design, and whether you prefer a neater appearance or greater adaptability. By evaluating these factors, you can select the system that best fits your needs, ensuring safety, functionality, and visual harmony.

Frequently Asked Questions

How Do Environmental Conditions Affect the Safety of L Track and S Track Systems?

Environmental conditions directly impact the safety of L Track and S Track systems. You should consider the environmental impact, such as moisture, temperature changes, and debris, which can affect system durability. Weather resilience is vital, as extreme conditions like rain or heat can weaken components or cause malfunctions. Regular inspections and proper maintenance help guarantee safety, regardless of environmental challenges, keeping your system reliable and secure over time.

Are There Industry Standards or Certifications That Verify Track System Safety?

Think of industry standards like the lighthouse guiding safe practices. Certification programs such as OSHA, ANSI, and ISO verify that track systems meet essential safety criteria. These standards guarantee your L track or S track system is reliable and compliant. Always check for proper certifications, as they reflect adherence to industry standards, reducing risk and enhancing safety. Trust in certified systems to keep your workspace secure, much like a lighthouse guards ships at sea.

What Are the Common Installation Mistakes That Compromise Track Safety?

You should watch out for common installation mistakes that compromise track safety, such as poor track alignment and unstable mounting. Misaligned tracks can cause uneven weight distribution, leading to failure, while insecure mounting can result in the track detaching under load. Always double-check alignment during installation and make sure mounting points are solid and properly secured. Proper installation is vital for maintaining track system safety and longevity.

How Does User Weight Distribution Impact Track System Performance?

Your weight distribution markedly impacts track system performance. By ensuring proper load balancing, you prevent uneven stress that can cause derailments or damage. When you distribute weight evenly across the track, it maintains stability and reduces wear on components. Focus on balanced weight placement, avoid overloading one side, and regularly check for shifts. This proactive approach helps keep your track system running smoothly, safe, and durable over time.

Can Track Systems Be Safely Modified or Customized After Installation?

Yes, you can safely modify or customize track systems, but you must prioritize modification safety. Always consult the manufacturer or a professional before making changes to guarantee compatibility and safety standards. Proper track customization enhances performance and fits your needs, but improper modifications can compromise stability and safety. Follow recommended guidelines, use appropriate tools, and verify all modifications to prevent accidents and ensure reliable system operation.

Conclusion

Think of your track system as the sturdy foundation of a bridge—you want it to support your journey safely. By understanding the differences, debunking myths, and choosing quality materials, you guarantee your path remains secure. When you install and maintain it properly, you’re building a reliable route that stands the test of time. Stay informed and confident—your safety depends on the bridge you choose to walk on every day.