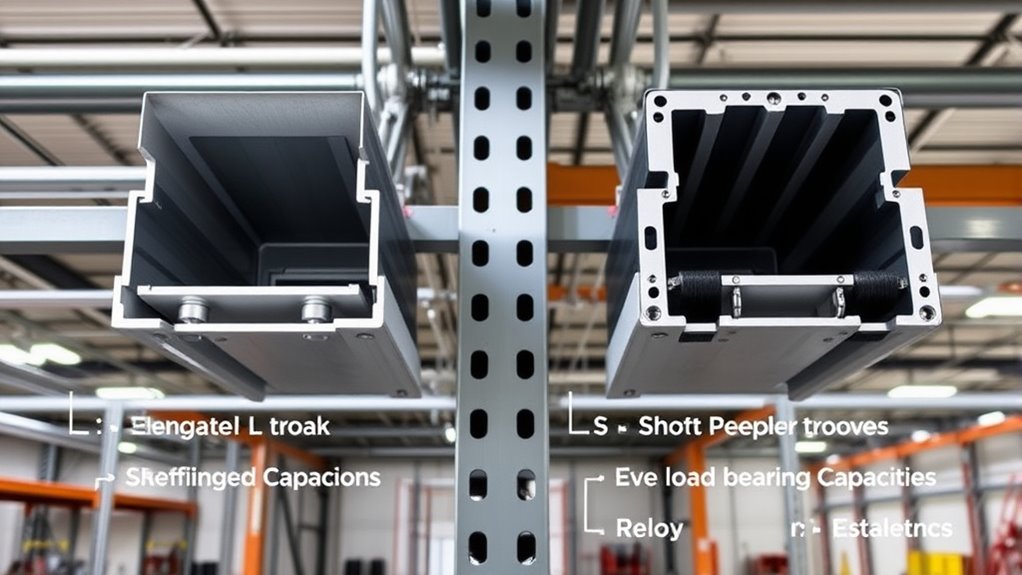

To avoid mistakes in L Track vs S Track systems, start by understanding their load capacities and guarantee compatibility with your existing setup. Don’t choose based solely on price—prioritize durability and quality materials. Consider space constraints, installation requirements, and safety standards to prevent costly errors. Consulting industry experts can help you make informed decisions, ensuring long-term performance. Keep these tips in mind, and you’ll be better equipped to select the right track system for your needs.

Key Takeaways

- Ensure compatibility with existing infrastructure and confirm load capacity to prevent safety and system failures.

- Verify safety standards and consult professionals to meet industry requirements and avoid costly mistakes.

- Choose durable materials over cheaper options to enhance longevity and reduce maintenance costs.

- Follow manufacturer installation instructions carefully to prevent misalignment and damage.

- Plan for future expansion and flexibility to adapt to long-term operational needs.

Overlooking the Differences in Load Capacity

Many people overlook the differences in load capacity between L Track and S Track systems, which can lead to safety issues and equipment damage. Understanding load capacity is vital because it determines how much weight the track can support safely. If you choose a track with insufficient load capacity, your equipment may become unstable or fail, risking injury and costly repairs. Equally important is equipment compatibility; not all tracks are designed to hold every type of gear, so mismatched systems can create unsafe conditions. Always check the maximum load capacity of the track and verify it matches your equipment’s weight. Properly evaluating these factors helps prevent accidents and prolongs your gear’s lifespan, keeping your setup both safe and reliable. Additionally, considering the design features of each track system can influence how well it performs under load and impacts overall safety.

Ignoring Compatibility With Existing Equipment

You need to guarantee your new track system works seamlessly with your current equipment. Overlooking connector compatibility or infrastructure requirements can cause costly setbacks. Checking existing system compatibility upfront saves time and prevents installation frustrations. Additionally, verifying juice yield from citrus fruits can help determine if your juicing equipment is efficient enough for your needs.

Existing System Compatibility

While evaluating system compatibility, it’s essential to determine how well the new L Track or S Track integrates with your existing infrastructure. Compatibility issues can affect railway electrification, making sure your power systems align correctly. If your current setup relies on specific track maintenance routines, switching to an incompatible track type could lead to increased costs or delays. Consider whether the new track’s specifications match your existing standards, such as gauge and wiring configurations. Overlooking these factors may result in system failures or the need for extensive modifications, which can be costly and time-consuming. Ensuring compatibility helps you avoid operational hiccups, maintains safety, and preserves the efficiency of your railway network. Additionally, understanding track technology can help you select the most suitable track system for your needs, preventing future disruptions and optimizing overall performance.

Connector Compatibility Issues

Compatibility issues often arise when connecting new L Track or S Track systems with existing equipment, and overlooking these can cause significant operational setbacks. One common problem is material durability; incompatible connectors may wear out quickly or fail under stress, leading to costly repairs or replacements. Additionally, you might notice that connector styles differ, affecting the aesthetic appeal of your setup. Poorly matched connectors can create visible gaps or uneven lines, detracting from a sleek, professional look. To avoid these issues, verify connector compatibility before installation. Ensuring that connectors are designed for the specific track material and style will help maintain both the durability of your system and its visual appeal. Don’t overlook this step—it’s essential for seamless integration and long-term performance.

Infrastructure Compatibility Checks

Before installing new L Track or S Track systems, it’s essential to verify that they will work seamlessly with your existing infrastructure. Check the power supply compatibility to ensure your current electrical setup can support the new system’s energy demands without overloads or outages. Additionally, confirm control system integration, making sure that your existing control units can communicate effectively with the new tracks. Failing to address these aspects can lead to operational hiccups or costly rewiring later. Take measurements and review specifications to identify potential conflicts. Consulting with professionals can help you avoid surprises. Ensuring compatibility upfront saves time, reduces risks, and guarantees your new track system functions smoothly within your established infrastructure.

Choosing Based Solely on Cost Without Assessing Durability

Choosing a track solely based on cost might seem like a good way to save money upfront, but it can lead to costly problems later. Focusing only on initial price ignores the importance of resilience, which impacts long-term maintenance and safety. Conducting a proper cost analysis helps you weigh expenses against durability and aesthetic appeal. Cheaper tracks may wear out quickly or fail prematurely, increasing replacement costs. Additionally, understanding bedroom design principles can help you select more durable and stylish options that stand the test of time. Here’s a quick comparison:

| Aspect | Low-Cost Track | Higher-Quality Track | Long-Term Value |

|---|---|---|---|

| Durability | Susceptible to damage | Resists wear and tear | Cost-effective over time |

| Aesthetic Appeal | May look cheap | Sleek, professional finish | Maintains appearance |

| Cost Analysis | Lower initial expense | Higher initial, saves money | Better investment overall |

Prioritize resilience to avoid costly repairs and ensure your investment lasts.

Neglecting to Consider Track Length and Space Constraints

Failing to contemplate the length of the track and the available space can lead to installation issues and operational inefficiencies. You need to consider track weight considerations because longer tracks may require stronger supports, affecting stability and safety. Ignoring space constraints can result in tracks that are too tight or too loose, impacting smooth operation. Additionally, track length influences aesthetic integration; a track that’s too long or short can disrupt your design flow. Measure your area carefully to ensure the track fits comfortably without crowding or leaving awkward gaps. Proper planning prevents costly adjustments later. By balancing track weight considerations with your space limitations, you ensure a seamless installation that functions well and looks integrated into your environment. Moreover, understanding relationship dynamics can help in planning optimal layout and usage, ensuring your tracks meet both functional and aesthetic needs.

Failing to Understand the Installation Process and Requirements

Understanding the installation process and requirements is essential to guarantee your track functions smoothly and safely. You need to be aware of installation prerequisites, such as proper wall support and space clearance, to avoid future issues. Failing to review technical specifications can lead to misaligned components or incompatible parts, compromising safety and performance. Ignoring these details may cause delays or costly adjustments during installation. Make sure you understand the mounting techniques, electrical connections, and weight limits specified by the manufacturer. Reading the installation manual thoroughly helps you identify essential prerequisites and technical specifications. Additionally, considering automation’s role in business intelligence can help you plan for future upgrades that enhance efficiency. By doing so, you assure that your L track or S track is installed correctly from the start, reducing the risk of problems and enhancing longevity and safety.

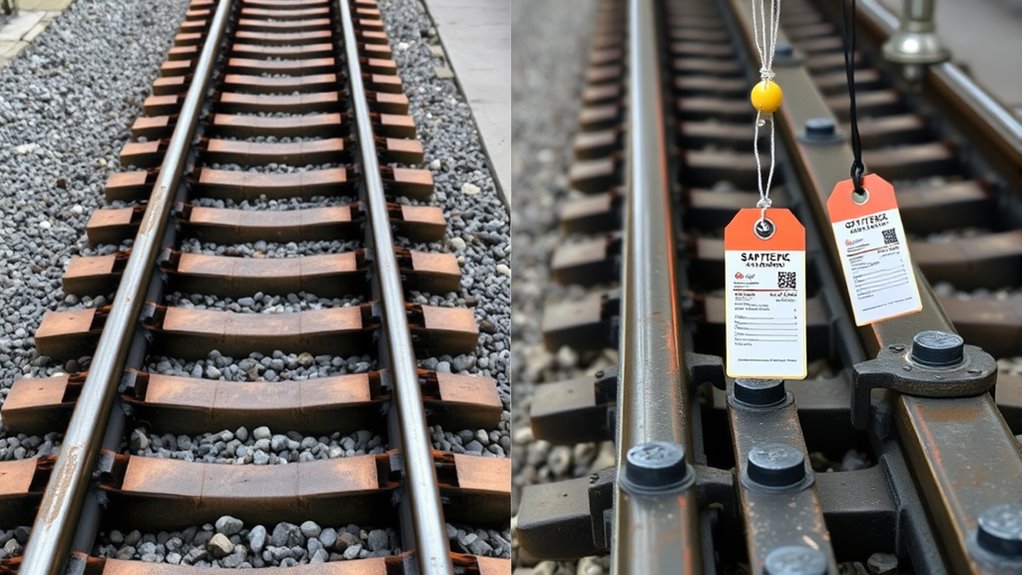

Underestimating Maintenance and Longevity Factors

Many people underestimate how much regular maintenance and long-term wear can impact the performance of L track and S track systems. Over time, factors like track material and installation techniques influence durability and functionality. Neglecting routine checks can lead to issues such as loose fittings or material degradation, reducing safety and lifespan. To ensure longevity, consider:

- Monitoring the track material for corrosion or damage

- Regularly inspecting and tightening fasteners and connections

- Choosing high-quality installation techniques suited for your environment

Understanding that maintenance needs vary based on track material helps prevent costly repairs. Proper upkeep not only extends the lifespan of your tracks but also maintains their smooth operation and safety standards over time. Don’t underestimate how proactive care can save you money and frustration down the line.

Not Evaluating Safety Features and Compliance Standards

You need to prioritize safety by checking certifications and reviewing compliance standards before making a decision. Don’t overlook emergency features that can protect users in critical situations. Ensuring these aspects are in place helps you avoid costly mistakes down the line. Additionally, understanding local safety regulations can provide further assurance of the equipment’s reliability and adherence to public health standards.

Check Safety Certifications

Are safety certifications genuinely reliable indicators of a track system’s quality? Not entirely. While certifications can confirm compliance, they don’t always guarantee suitability for your specific needs. When checking certifications, focus on details like load capacity and equipment compatibility to ensure the system can handle your intended use. Certifications should also verify that the track meets rigorous safety standards, but don’t rely solely on them. Look for certifications from reputable organizations, and consider these points:

- Confirm that certifications cover your required load capacity.

- Ensure the track’s safety features align with your equipment compatibility needs.

- Verify that certifications are current and recognized within the industry.

- Regular monitoring of AI safety measures is essential to adapt to emerging vulnerabilities and ensure ongoing safety.

Prioritizing these factors helps you avoid installing a system that might be unsafe or incompatible, even if it’s certified.

Review Compliance Standards

While safety certifications provide a baseline, reviewing compliance standards offers a deeper understanding of a track system’s reliability. You should examine track material properties to verify they meet industry standards for durability and performance. Pay attention to how installation techniques align with compliance requirements, as improper methods can compromise the system’s integrity. Confirm that the materials used are suitable for your environment and won’t degrade prematurely. Standards often specify specific installation procedures that help prevent issues like loosening or misalignment. Additionally, material properties play a crucial role in ensuring the longevity and safety of the system. By thoroughly reviewing these standards, you can avoid potential pitfalls that might not be evident from certifications alone. This proactive approach ensures the track system you choose not only meets safety benchmarks but also maintains long-term performance.

Assess Emergency Features

Evaluating emergency features is a critical step in selecting an L Track or S Track system because these elements directly impact safety during unexpected events. You need to take into account how well the system handles emergencies, including its load capacity during evacuations or power failures. Ensure the emergency features are reliable and easy to activate when needed. Incorporating dog names that evoke reliability and resilience can also be beneficial in designing emergency protocols.

Key points to assess include:

- The robustness of emergency release mechanisms

- The system’s load capacity during emergency operations

- Compatibility with safety accessories like alarms or lighting

Relying on Limited or Inaccurate Technical Data

Relying on limited or inaccurate technical data can lead to costly mistakes when choosing between L Track and S Track systems. If you don’t review detailed technical specifications, you risk selecting a track that doesn’t meet your load requirements or installation conditions. Material quality is also vital; overlooking details about durability and corrosion resistance might result in premature system failure. Inaccurate data can cause mismatched components, leading to safety issues or increased maintenance costs. Always verify the source of your technical information and confirm it reflects real-world performance. Relying on incomplete or outdated data hampers your ability to make informed decisions, potentially resulting in system inefficiency or failure. Precise, detailed technical specifications are essential for choosing the right track type for your needs.

Neglecting Future Expansion or Flexibility Needs

You need to ensure how your system will adapt as your needs grow. Failing to assess long-term compatibility or plan for upgrades can limit future flexibility. Addressing these points now ensures your setup remains effective over time.

Assess Long-Term Compatibility

Neglecting to contemplate future expansion or flexibility needs can lead to significant problems down the line. When evaluating long-term compatibility, consider how the track material aligns with your future plans. Will the current installation timing accommodate potential upgrades? Failing to analyze these factors can result in costly replacements or modifications later.

To make the right choice, think about:

- Compatibility of track material with upcoming system requirements

- Ease of integration with future components

- Flexibility in adjusting installation timing for expansion needs

Plan for System Upgrades

Planning for system upgrades guarantees your installation remains functional and cost-effective as your needs evolve. When choosing track material, consider future expansion and flexibility. Opt for durable, adaptable materials that can accommodate additional components or modifications later. Pay close attention to installation techniques; guarantee they allow easy access for upgrades without damaging existing work. Using modular track designs and flexible mounting options can save time and money down the line. Avoid rigid setups that restrict future additions. Incorporate extra capacity where possible, even if not immediately necessary. This foresight ensures your system can grow with your requirements, minimizing costly rework. Proper planning now helps maintain system performance, reduces downtime, and extends overall longevity. Always think ahead to avoid costly mistakes and ensure seamless upgrades in the future.

Making Decisions Without Consulting Industry Experts

Making decisions without consulting industry experts can lead to costly mistakes and overlooked opportunities. Without their insights, you might miss critical industry standards or misjudge ideal material selection, impacting system performance and longevity. Experts bring valuable experience, ensuring your choices align with current best practices and regulatory requirements.

Consider these points:

- Relying on expert advice helps you stay updated on industry standards.

- They provide guidance on material selection for durability and safety.

- Consulting specialists can identify potential issues early, saving time and money.

Skipping expert input can result in overlooked details that compromise system efficiency. By involving industry professionals, you ensure your L Track or S Track installation adheres to current standards, reducing risks and enhancing overall performance.

Frequently Asked Questions

How Do Load Capacity Differences Impact Track Longevity?

Your load capacity directly impacts track longevity; higher loads put more stress on the tracks, causing faster wear and tear. If you overload the L track or S track, you risk structural damage and reduced lifespan. To guarantee longer track life, always match the load capacity to your application’s demands, avoid overloading, and regularly inspect the tracks for signs of stress. Proper maintenance helps maximize track longevity and performance.

What Compatibility Issues Should I Consider With Existing Equipment?

When considering compatibility with existing equipment, you should check track wiring to guarantee it matches your control system. Make sure the control compatibility aligns with your current setup, avoiding issues like incompatible voltages or signals. Test connections thoroughly and verify that your control devices can operate seamlessly with the new track type. This proactive approach prevents operational hiccups and guarantees smooth integration with your existing infrastructure.

How Does Track Material Choice Affect Durability Over Time?

It’s worth investigating whether a track’s material impacts its durability over time. Generally, the track surface and material resilience are vital. Harder materials like steel tend to withstand wear longer, but softer surfaces may offer better shock absorption. Your choice influences longevity; high-quality, resilient materials resist corrosion and deformation, reducing maintenance needs. Selecting the right track material ensures your setup remains robust and reliable, saving you money and effort in the long run.

What Safety Standards Are Essential for Track Installation?

You must follow essential safety standards during track installation, focusing on proper rail height and installation methods. Guarantee the rail height is consistent to prevent accidents, and use approved installation techniques to secure the tracks effectively. Regular inspections and adherence to manufacturer guidelines help maintain safety. By prioritizing these standards, you reduce risks and ensure a safe, reliable setup for both L and S track systems.

How Can Future Expansion Influence Current Track Selection?

Sure, pick a track just for today’s needs, but don’t forget future expansion. It’s ironic—you might think your current railway signaling and track alignment are perfect, only to find they limit growth tomorrow. Planning ahead guarantees your tracks can handle future trains and signaling upgrades without costly rework. Think long-term, and you’ll save yourself headaches, ensuring smooth expansion without sacrificing safety or efficiency.

Conclusion

Avoid these mistakes, and you’ll be unstoppable in choosing the perfect track! Miss them, and you risk disaster on a scale that could shake the very foundations of your project. Don’t let overlooked details or hasty decisions turn your investment into a colossal nightmare. Stay informed, consult experts, and make smart choices—because when it comes to track selection, one mistake could spell catastrophe for your entire operation. Act wisely, and build with confidence!