When comparing 2D, 3D, and 4D rollers, focus on their geometric features, such as diameter, curvature, and length, which impact contact and load distribution. Remember to calculate volume and surface area for load capacity and durability, especially in 3D and 4D models. Trajectory and movement calculations ensure smooth operation. Accurate material and tolerance checks prevent failures, so pay attention to these vital calculations for best performance—your next steps will uncover how to master them.

Key Takeaways

- Understand the geometric differences: diameter, curvature, and length impact contact area and force distribution.

- Account for material properties: friction coefficients, durability, and surface finish influence performance and safety.

- Perform precise kinematic calculations: velocity, acceleration, and trajectory analysis ensure optimal movement and effectiveness.

- Measure with appropriate tools: laser systems must match roller geometry for accurate surface flatness, alignment, and tolerances.

- Validate calculations and designs: cross-check results, consider ergonomic factors, and prevent errors to ensure durability and functionality.

Understanding the Basic Principles Behind 2D, 3D, and 4D Rollers

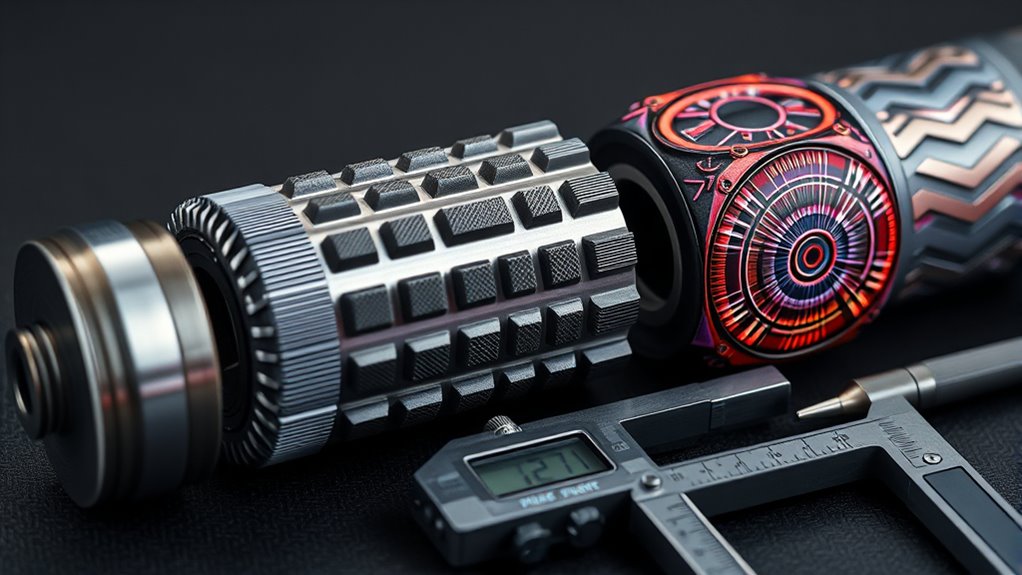

To understand the differences between 2D, 3D, and 4D rollers, understanding their basic principles is essential. 2D rollers feature flat surfaces that mainly focus on targeted pressure, making them effective for basic massage or stretching. As you move to 3D rollers, they incorporate shape deformation, allowing the surface to mold more closely to your body’s contours, which enhances comfort and effectiveness. Friction coefficients also vary, impacting how the roller interacts with your skin and muscles—higher friction offers deeper tissue stimulation, while lower friction provides a smoother experience. 4D rollers take this further by integrating multi-directional movements, creating dynamic shape deformation that mimics real massage techniques. These advancements influence how each roller type applies pressure and interacts with your muscles, tailoring treatment to your needs. Additionally, the material choice of the roller can significantly affect its durability and performance during use.

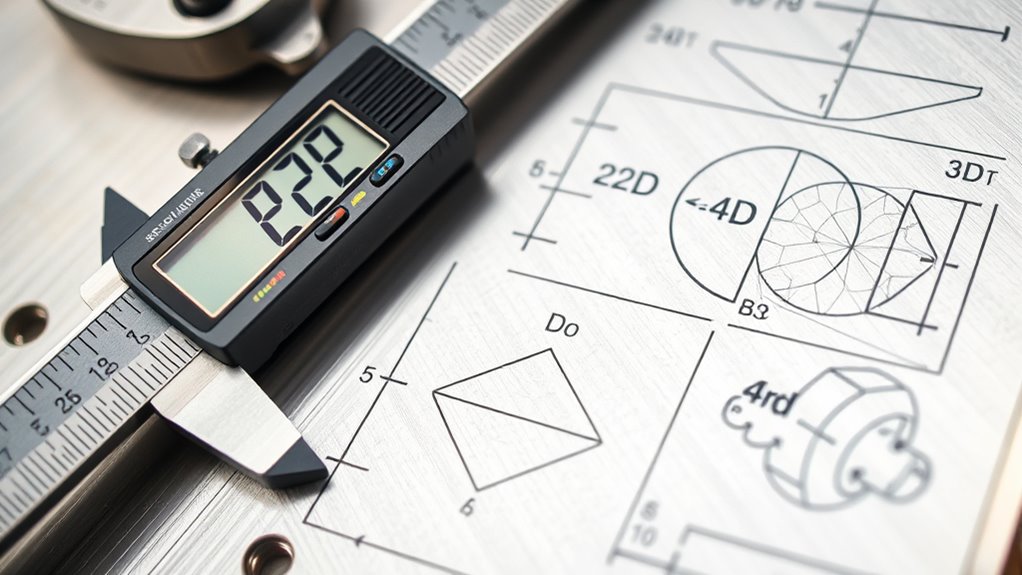

Key Geometric Calculations for Accurate Roller Selection

Selecting the right roller depends heavily on understanding its geometric properties. Precise calculations guarantee ideal performance, especially when considering lubrication techniques and surface finishing. Key measurements include diameter, length, and curvature. These factors influence load capacity, friction, and wear. Use the table below to guide your selection:

| Property | Calculation Method | Impact on Performance |

|---|---|---|

| Diameter | Measure across the roller’s widest point | Affects contact area and lubrication flow |

| Curvature | Radius of the roller’s surface | Influences surface finishing quality |

| Length | Distance between roller ends | Determines coverage area and load distribution |

Accurate geometry helps prevent issues like uneven surface finishing and lubrication failure, ensuring longevity and efficiency. Understanding the geometric properties of rollers is essential for optimal selection and performance.

Volume and Surface Area Considerations in 3D and 4D Rollers

Understanding the volume and surface area of 3D and 4D rollers is essential for maximizing their performance and durability. As you analyze these aspects, consider how kinematic complexity influences their design, affecting how they distribute forces and resist wear. Dimensional scaling plays a key role; larger rollers have proportionally different surface areas and volumes, impacting load capacity and heat dissipation. In 3D and 4D rollers, surface area isn’t just about size—it influences friction and contact efficiency. Calculating these parameters accurately helps you select the right roller for specific applications, ensuring ideal performance. Additionally, electric bike components such as motors and batteries often require precise calculations of surface area and volume to optimize heat management and efficiency. By understanding the relationships between volume, surface area, and the kinematic complexities involved, you can make informed decisions that improve longevity and effectiveness.

Movement and Trajectory Calculations for Dynamic Rolling

When analyzing dynamic rolling, calculating movement and trajectory is crucial for predicting how rollers behave under various forces. Kinematic analysis helps you understand the position, velocity, and acceleration of the roller at any given moment. By applying principles of motion prediction, you can determine the roller’s path and how it responds to external factors like friction, gravity, and applied forces. Accurate calculations allow you to anticipate changes in direction, speed, and stability during operation. This process involves analyzing the roller’s rotational and translational motion, especially in complex systems like 3D and 4D rollers. Mastering these calculations ensures peak performance, minimizes unexpected behavior, and enhances safety in dynamic environments.

Material Compatibility and Load-Bearing Calculations

Accurate movement and trajectory calculations depend heavily on choosing materials that can withstand the forces involved without degrading performance. Material strength is vital, as it determines the roller’s ability to support loads without deformation or failure. You must consider the load-bearing capacity based on expected weight, speed, and cycle frequency. Equally important is the surface finish, which affects friction, wear, and overall durability. A smooth, well-finished surface minimizes resistance and prevents material fatigue over time. When selecting rollers, ensure the materials are compatible with your application’s environment—resisting corrosion, temperature extremes, and chemical exposure. Proper load-bearing calculations combined with ideal material choices help maintain precise movement, prolong roller lifespan, and guarantee your system operates reliably under all conditions. Additionally, understanding the specific Kia Tuning modifications can influence the selection of components to ensure compatibility and optimal performance.

Precision and Tolerance Checks for Different Roller Types

You need to guarantee your rollers meet specific manufacturing tolerance standards and measurement accuracy requirements. Skipping these checks can lead to performance issues or premature failure. Let’s explore how different roller types demand different precision and tolerance assessments. Incorporating proper organization into your inspection process ensures that all components are accounted for and properly evaluated before deployment.

Manufacturing Tolerance Standards

Manufacturing tolerance standards are critical to ensuring the performance and longevity of different roller types. These standards depend heavily on material properties, which influence how rollers respond to stress and wear. For example, metal rollers require strict tolerances due to their precise manufacturing processes, ensuring smooth operation and minimal vibration. Plastic or composite rollers may have slightly looser tolerances but still need to meet specific standards for durability. Consistent adherence to these standards guarantees that each roller functions correctly within its design parameters. By controlling manufacturing processes—such as machining, molding, or finishing—you can ascertain the tolerances are maintained. This precision minimizes defects, reduces downtime, and extends the lifespan of the rollers, ultimately leading to better machine performance and reliability. Additionally, understanding regional culinary standards can influence the choice of materials and finishing techniques used in manufacturing to meet specific industry requirements.

Measurement Accuracy Requirements

Ensuring measurement accuracy is essential for maintaining the proper function and durability of 2D, 3D, and 4D rollers. To achieve this, you need reliable calibration techniques and precise measurement tools. Regular calibration of your measurement tools guarantees consistent results, reducing errors that could compromise roller performance. When checking tolerances, use high-precision instruments like micrometers, dial gauges, or laser measurement systems suited for each roller type. For 2D rollers, focus on flatness and alignment; for 3D and 4D rollers, consider complex geometries and multidimensional tolerances. Accurate measurements help identify deviations early, allowing timely adjustments. By adhering to strict calibration practices and using the right measurement tools, you can maintain tight precision standards and ensure your rollers perform optimally over their lifespan. Additionally, understanding headphone jacks can help ensure proper connections when testing or troubleshooting measurement devices.

Common Pitfalls and How to Check Your Calculations Before Use

Mistakes in calculations are common pitfalls when working with rollers, and overlooking small errors can lead to major issues during implementation. To prevent this, double-check your work before use. First, review your calculations in the design software to ensure all measurements and parameters are correct. Second, verify that your ergonomic design assumptions align with real-world conditions, avoiding overestimations. Third, cross-reference your results with manual calculations or alternative software tools to catch discrepancies. These steps help identify errors early, saving time and resources. Additionally, staying informed about advances in AI-powered processing can help optimize your validation process integration of AI in device performance. Remember, meticulous checking guarantees your roller design performs safely and efficiently. By paying attention to detail and not skipping validation steps, you can confidently move forward with your project.

Frequently Asked Questions

How Do Environmental Factors Affect Roller Performance Calculations?

Environmental factors like temperature, humidity, and ambient conditions substantially impact roller performance calculations. You need to take into account material properties, as different materials react uniquely to these conditions, affecting durability and friction. For example, high humidity may cause swelling or slipping, while temperature variations can alter material flexibility. By accounting for these environmental factors, you guarantee precise calculations, leading to the best roller selection and longer-lasting performance in real-world conditions.

What Are the Safety Margins to Consider in Roller Load Calculations?

Think of safety margins as your roller’s safety net, catching surprises along the way. You should include safety thresholds and margin buffers of at least 20-30% in your load calculations. This extra wiggle room accounts for unexpected loads, wear, or environmental changes. By doing so, you guarantee your rollers operate smoothly without risking overloads or failures, keeping your equipment safe and your operations running seamlessly.

How Often Should Calibration Checks Be Performed on Rollers?

You should perform calibration checks on rollers at least once every six months, but more frequent calibration frequency might be needed depending on usage intensity. Incorporate these checks into your maintenance scheduling to guarantee ideal performance and safety. Regular calibration helps catch drift early, preventing costly errors and downtime. Keep a detailed log of calibration dates and results, and adjust your schedule if you notice any inconsistencies or performance issues.

Can Software Simulations Replace Manual Calculation Verification?

Software simulations can’t fully replace manual calculation verification because they may overlook factors like material fatigue and thermal expansion, which impact roller performance. When you rely solely on simulations, you risk missing subtle issues that could lead to failure. Manual checks help catch these nuances, ensuring your rollers operate safely and efficiently. Combining both methods gives you a thorough understanding, reducing the risk of unexpected breakdowns.

What Are the Signs Indicating a Need for Recalculating Roller Specifications?

Think of your rollers like a car’s tires; if they show uneven wear or wobble, it’s time for a recalculation. Signs include increased material wear, inconsistent output, or lubrication quality issues. If you notice rollers aren’t performing smoothly or efficiency drops, reassess their specifications. Don’t wait for a breakdown—regular checks help you catch these signs early, ensuring your equipment runs at its best and lasts longer.

Conclusion

Understanding the differences between 2D, 3D, and 4D rollers is essential for accurate selection and best performance. Did you know that precise calculations can reduce equipment failures by up to 30%? By mastering geometric, volume, and movement considerations, you’ll guarantee your rollers handle loads efficiently and reliably. Always double-check your measurements and tolerances—skipping these steps could cost you time and money. With careful planning, you’ll maximize your roller’s lifespan and functionality.